ISO 9001 : 2015

Product categories

- Air blowers (11)

- DOUBLE STAGE VACUUM PUMP (55)

- Monoblock Vacuum Pumps (11)

- oil seal vacuum pumps (63)

- Roots Blowers (7)

- Single Stage Vacuum Pumps (62)

- Single Stage Watering Vacuum Pump (20)

- Two Stage Water Ring Vacuum Pumps (14)

- VACUUM PUMPS (63)

- water ring vacuum pumps (49)

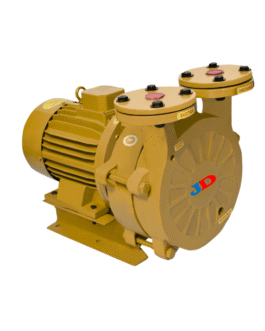

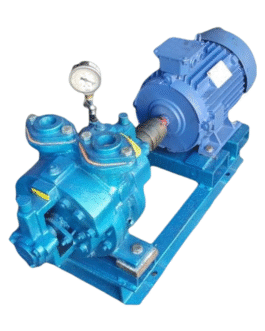

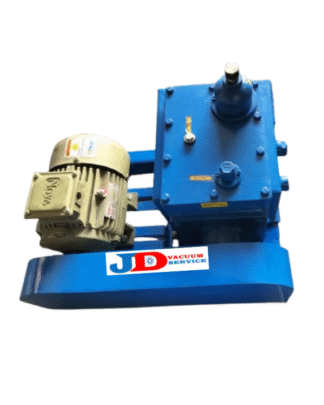

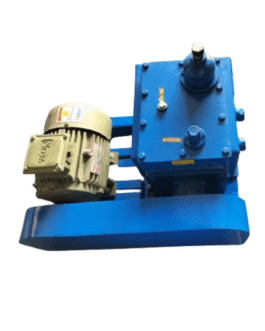

3 HP Single Stage Water Ring Vacuum Pump – JDWV 1

JDWV 1 Water Ring Vacuum Pump is a high-performance and reliable solution designed for a wide range of industrial applications. Built with precision engineering, it ensures smooth operation, long service life, and low maintenance requirements.

- Model Type: JDWV 1

- Stage: Single Stage

- Recommended Motor Power: 3 HP

- Speed: 2850 RPM

- Suction Capacity: 50 m³/hr

- Water Consumption: 7 L/min (approx.)

- Cooling Requirement: Continuous water supply

- Duty Cycle: Suitable for continuous duty

- Construction Material: Cast Iron / Stainless Steel (optional)

Description

Operating Principle

The 3 HP Single Stage Water Ring Vacuum Pump operates on the liquid ring principle, where water acts as the sealing medium. As the impeller rotates, a ring of water is formed inside the casing. This ring creates a series of spaces that expand and contract, drawing in air or gases through the suction port and discharging them at the outlet.

The process is smooth, vibration-free, and highly reliable, which is why this 3 hp single stage unit is preferred by many.

Why Choose 3 HP Single Stage Water Ring Vacuum Pump?

- Durability – Designed for long service life even in demanding industrial environments, making it an excellent choice when considering a 3 hp single stage model.

- Efficiency – Provides a steady vacuum with low energy consumption, a key advantage of the 3 hp version.

- Versatility – Suitable for handling moist air, gases, and even light vapors.

- Low Maintenance – Simple design ensures reduced downtime and easy servicing.

- Proven Performance – Trusted by industries such as pharmaceuticals, packaging, chemicals, and more.

Advantages

- Reliable performance with consistent vacuum levels, typical of 3 hp single stage vacuum systems.

- Energy-efficient design for reduced operational costs.

- Low noise and vibration during operation.

- Easy to maintain and operate.

- Suitable for continuous duty applications.

Salients Features

- Completely Reliable Operation, synonymous with the efficiency of 3 hp single stage water ring pumps.

- Easy Maintenance.

- Low Power And Water Consumption.

- Rugged Construction For Heavy Duty Application.

- Simple And Trouble-Free Operation.

- Suitable For Low And High Vacuum Applications.

- No Metallic Contact Inside Pump.

- Leak Proof Sealing Arrangement Also Possible.

- Clean & Oil Free Discharge.

- Compression Takes Place With Small Temperature Rise and Smooth Discharge.

- Simplicity Of Rotating Parts Improves Reliability. Because of pump simplicity, a 3 hp single stage can be readily disassembled and reassembled on site by the end user.

Application

- Chemical Industry : Solvent recovery, Vacuum Distillation, Filtration, Gas Compression with efficient 3 hp single stage pumps.

- Pharmaceutical Industry : Crystallization(Evaporation), Recreation, Drying, Distillation.

- Power Industry : Turbine Gland Exhausting, Conveying of fly ash, Vacuum Priming, Vacuum Deaeration and condenser initial evacuation (hogging).

- Sugar Distillery Industries : Vacuum filtration.

- Plastic Industries : Extrusions, Degassing, drying, & conveying.

- Environmental Industry : Bottle Filling, Vacuum Priming, digester gas compression, wastewater disposal.

- Paper & Pulp Industries : Process Vacuum, Stock & White Water Deaeration, Head Box Compressor / Vacuum Pump.

- Packaging Industry : Vacuum packaging, production PET containers.

- Ceramic Industry : Air Removing,Vacuum Processing.

- Mining : Some Generic Applications In The Extraction Of Alumina From Bauxite, Copper, Titanium Dioxide, Iron Ore, Phosphate Or Coal, Are As Follows:

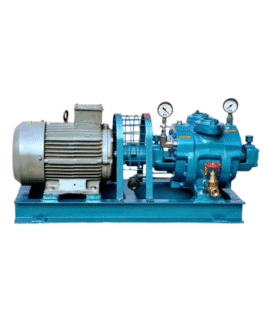

- Type: JDWV 1

- Motor Power: 3 HP (recommended)

- Speed: 2850 RPM for efficient performance

- Suction Capacity: 50 m³/hr – ideal for medium-scale operations

- Water Consumption: 7 L/min (approx.), ensuring cost-effective operation

- Design: Compact, robust, and durable construction

- Stage: Single stage water ring mechanism for stable vacuum generation

The JDWV 1 Water Ring Vacuum Pump is widely used in industries such as:

- Chemical processing

- Pharmaceuticals

- Food & beverage packaging

- Paper & pulp

- Autoclaves and sterilizers

- Plastic and textile industries