ISO 9001 : 2015

Product categories

- Air blowers (11)

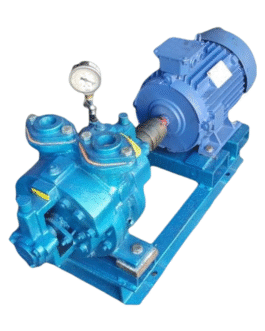

- DOUBLE STAGE VACUUM PUMP (55)

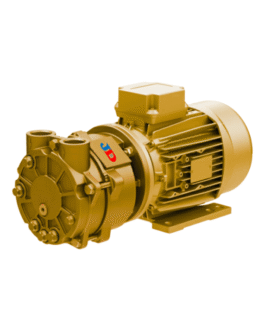

- Monoblock Vacuum Pumps (11)

- oil seal vacuum pumps (63)

- Roots Blowers (7)

- Single Stage Vacuum Pumps (62)

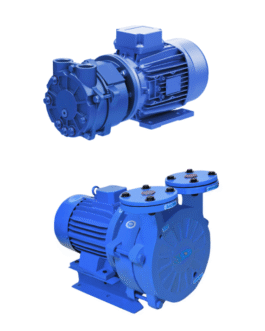

- Single Stage Watering Vacuum Pump (20)

- Two Stage Water Ring Vacuum Pumps (14)

- VACUUM PUMPS (63)

- water ring vacuum pumps (49)

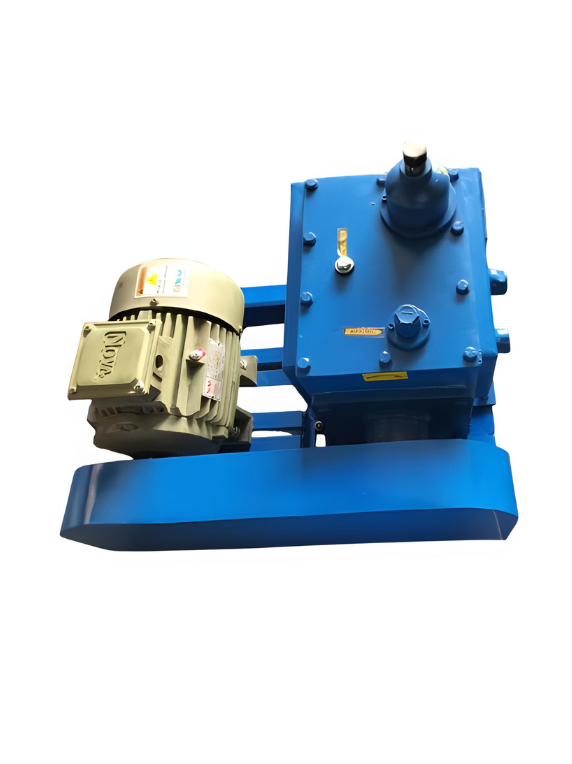

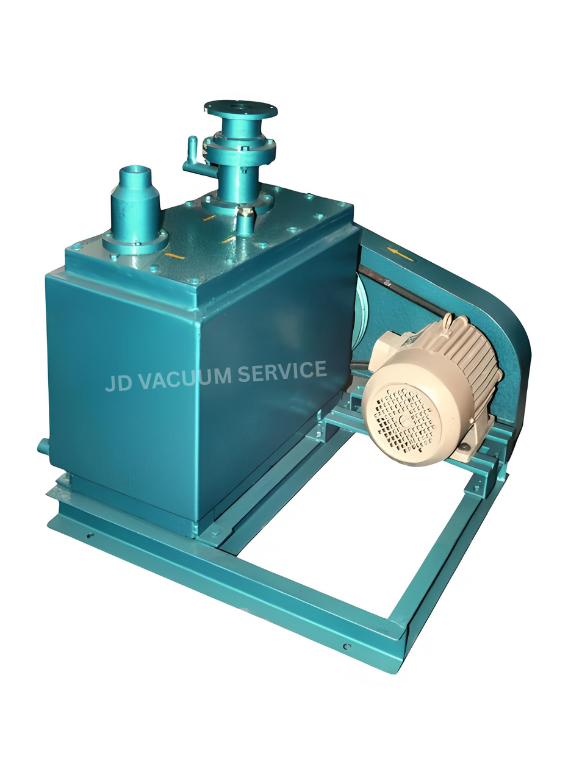

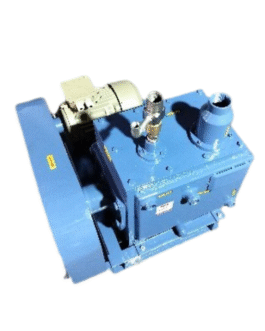

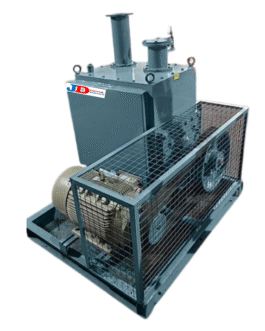

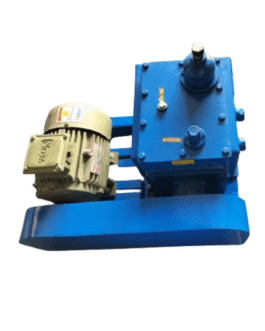

Vacuum Pump for Solvent Recovery and Crystallizer Systems

We are manufacturing a vacuum pump for solvent recovery and a Crystallizer Machine. These products are manufactured in compliance with international standards and norms, using high-quality raw materials procured from reliable market vendors.

- Type: Belt Drive Rotary Vane Pumps

- Power: 3 HP TO 20 HP

- Brand: JD VACUUM SERVICE

- Model Name/Number: JDO 50 TO 20000 LPM

- Usage/Application: Industrial

- Phase: 3 Phase

- Material: GRADED CAST IRON

- Motor Speed: 1440 RPM

- Packaging Type: WOODEN BOX

- Country of Origin: Made in India

Description

Vacuum Pump for Solvent Recovery – JD Vacuum Service

Experience exceptional performance with the Vacuum Pump for Solvent Recovery, designed to deliver powerful suction, consistent flow, and stable vacuum levels across demanding industrial processes. Moreover, this pump ensures optimal solvent evaporation and condensation cycles, enabling you to recover valuable solvents efficiently.

Because it is built with precision engineering and robust components, it supports uninterrupted operation even in harsh working environments. As a result, industries such as pharmaceuticals, chemicals, laboratories, and essential oil extraction benefit from faster recovery rates and lower operational costs.

Advanced Solvent Processing with Maximum Safety

In addition to its exceptional performance, this vacuum pump enhances workplace safety by maintaining stable vacuum conditions during solvent evaporation. Its leak-proof sealing system prevents solvent vapors from escaping, while its advanced oil filtration ensures clean discharge. Furthermore, the pump incorporates a direct-drive or belt-drive mechanism (depending on model), delivering smooth, vibration-free operation. Consequently, your solvent recovery system performs more efficiently and lasts longer with reduced maintenance.

Technical Advantages:

- Enhanced Vapor Handling: Designed for handling high solvent vapor loads

- Thermal Protection: Automatic overload and heat protection

- High Chemical Resistance: Suitable for aggressive solvent environments

- Optimized Pumping Speed: Ensures consistent recovery cycles

- Service-Friendly Design: Easy access for maintenance and oil change

Built for Longevity and Low-Cost Operation

To ensure lasting performance, the Vacuum Pump for Solvent Recovery offers durable construction, low wear components, and reduced operating costs. Additionally, its energy-efficient motor helps minimize power consumption. Therefore, whether you run continuous solvent extraction or batch-based recovery operations, this pump delivers maximum yield with minimal downtime. Ultimately, its long-life components and smooth operation make it a reliable investment for industries seeking efficiency, savings, and uncompromised quality.

More Specifications:

- Oil Capacity: 0.7–6 Litres (depending on pump size)

- Flow Rate Stability: Maintains consistent vacuum flow under load

- Vapor Tolerance: High vapor handling capability for solvent-rich processes

- Installation: Compact footprint, easy integration into existing setups

- Optional Add-on: Moisture trap, vacuum regulator, gauge assembly, oil mist filter

SINGLE STAGE

| Model No. | Max Vacuum | Approx Oil Filling Ltrs. | Free Air Displacement Lt./min, c.f.m, m3/hr | Drive Motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 I | 0.05 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 I | 0.05 mbar | 2 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.25 | ||

| JDO-150 I | 0.05 mbar | 3 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 0.50 | ||

| JDO-300 I | 0.05 mbar | 5 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.00 | ||

| JDO-500 I | 0.05 mbar | 9 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 1.50 | ||

| JDO-750 I | 0.05 mbar | 10 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 2.00 | ||

| JDO-1000 I | 0.05 mbar | 10 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 2.00 | ||

| JDO-1500 I | 0.05 mbar | 25 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 3.00 | ||

| JDO-2000 I | 0.05 mbar | 25 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 3.00 | ||

| JDO-3000 I | 0.05 mbar | 32 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 5.00 | ||

| JDO-5000 I | 0.05 mbar | 36 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 7.50 | ||

| JDO-7500 I | 0.05 mbar | 60 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 10.00 | ||

| JDO-10000 I | 0.05 mbar | 66 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 15.00 | ||

| JDO-15000 I | 0.05 mbar | 68 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 22.00 | ||

| JDO-20000 I | 0.05 mbar | 70 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 25.00 | ||

DOUBLE STAGE

| Model No. | max vacuum | approx oil filling ltrs. | free air displacement Lt./min, c.f.m, m3/hr | drive motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 II | 0.005 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 II | 0.005 mbar | 3 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.50 | ||

| JDO-150 II | 0.005 mbar | 4 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 1.00 | ||

| JDO-300 II | 0.005 mbar | 7 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.50 | ||

| JDO-500 II | 0.005 mbar | 12 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 2.00 | ||

| JDO-750 II | 0.005 mbar | 14 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 3.00 | ||

| JDO-1000 II | 0.005 mbar | 15 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 3.00 | ||

| JDO-1500 II | 0.005 mbar | 30 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 5.00 | ||

| JDO-2000 II | 0.005 mbar | 35 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 5.00 | ||

| JDO-3000 II | 0.005 mbar | 40 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 7.00 | ||

| JDO-5000 II | 0.005 mbar | 42 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 10.00 | ||

| JDO-7500 II | 0.005 mbar | 65 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 15.00 | ||

| JDO-10000 II | 0.005 mbar | 75 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 20.00 | ||

| JDO-15000 II | 0.005 mbar | 80 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 25.00 | ||

| JDO-20000 II | 0.005 mbar | 80 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 30.00 | ||

- Exceptional vacuum stability for accurate solvent recovery

- Optimized for crystallization and evaporation processes

- Corrosion-resistant materials for chemical compatibility

- Energy-efficient motor for low power consumption

- Quiet operation with minimal maintenance needs

- Designed for continuous industrial applications

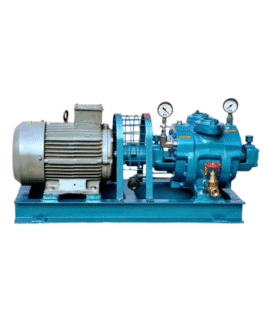

- Vacuum Range: Up to 29.9 inHg (0.5 mbar)

- Capacity: 20 – 5000 m³/hr (customizable)

- Construction Material: Stainless Steel / Cast Iron with anti-corrosion coating

- Cooling System: Water-cooled or air-cooled options available

- Drive Type: Direct drive or belt-driven configuration

- Applications: Solvent recovery, crystallization, distillation, drying, and filtration

- Reduce Solvent Waste: Recover up to 99% of valuable solvents.

- Enhance Product Quality: Achieve consistent crystal structure and purity.

- Lower Operational Costs: Save on energy and maintenance expenses.

- Ensure Process Safety: Leak-proof and explosion-resistant design.

- Eco-Friendly Operation: Low noise, low emissions, and energy-efficient performance.