ISO 9001 : 2015

Product categories

- Air blowers (11)

- DOUBLE STAGE VACUUM PUMP (55)

- Monoblock Vacuum Pumps (11)

- oil seal vacuum pumps (63)

- Roots Blowers (7)

- Single Stage Vacuum Pumps (62)

- Single Stage Watering Vacuum Pump (20)

- Two Stage Water Ring Vacuum Pumps (14)

- VACUUM PUMPS (63)

- water ring vacuum pumps (49)

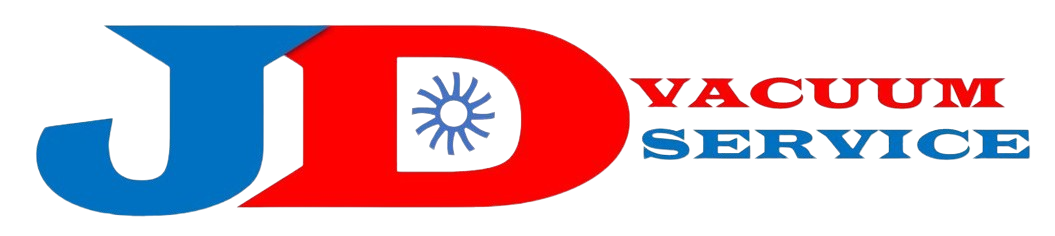

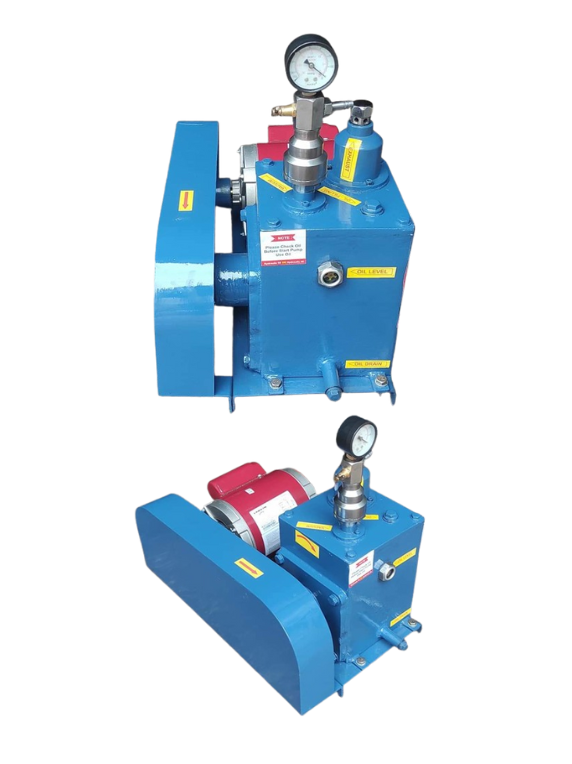

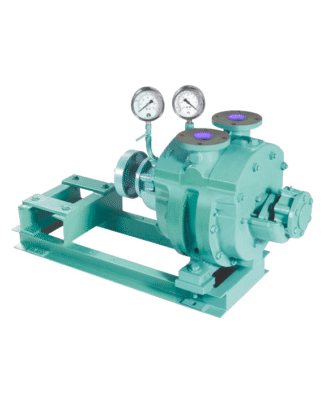

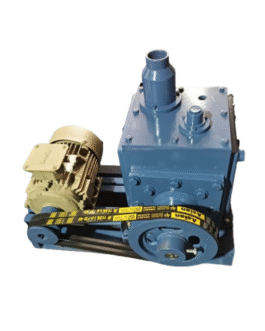

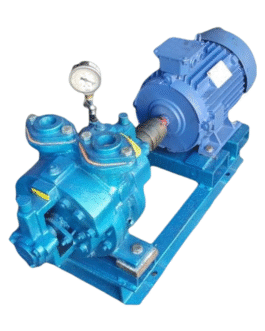

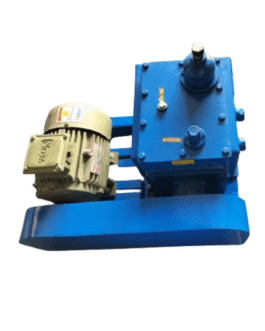

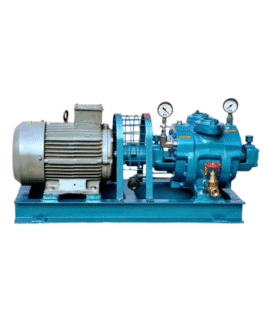

Industrial High Vacuum Pump

Experience powerful suction, long-lasting durability, and precision control with the Industrial High Vacuum Pump from JD Vacuum Service. Engineered for high performance, low maintenance, and reliable vacuum levels across diverse industrial applications.

- Type: Industrial High Vacuum Pump

- Capacity: 20–300 M³/Hr (varies by model)

- Ultimate Vacuum: Up to 0.5 mbar

- Motor Power: 0.5 HP to 20 HP

- Cooling System: Air/Oil-Cooled

- Lubrication: Oil-Sealed Mechanism

- Noise Level: Low-noise Engineering

- Applications: Industrial Processing, Chemical, Pharma, Packaging, Labs

Description

Industrial High Vacuum Pump – Precision, Power & Performance

Discover the extraordinary efficiency of the Industrial High Vacuum Pump by JD Vacuum Service, engineered to deliver superior vacuum levels with consistent reliability. This high performance pump is designed for industries that demand precision, whether in manufacturing, pharmaceuticals, chemical processing, laboratories, or packaging. Moreover, its advanced engineering ensures stable vacuum output, faster evacuation time, and long operational life, allowing you to achieve optimum productivity without interruption.

Because of its robust build and smooth functionality, users can effortlessly maintain consistent performance even under continuous heavy duty use. As a result, this pump offers not only exceptional reliability but also the confidence needed for mission critical operations.

Key Advantages

- High pumping speed for rapid system evacuation

- Deep ultimate vacuum levels for precision processes

- Low noise and minimal vibration for smoother operation

- Heavy-duty construction for long lasting durability

- Energy-efficient design for reduced operational cost

Advanced Engineering, Low Maintenance & Maximum Durability

Built with cutting edge technology, this Industrial High Vacuum Pump integrates high grade materials, ensuring outstanding durability even in demanding environments. Additionally, its oil-sealed mechanism enhances long-term performance while minimizing wear and tear. The simplified maintenance design allows for quick servicing, making it an excellent choice for businesses seeking reduced downtime.

Thanks to its exceptional thermal stability, the pump maintains optimal performance even during extended operation. Furthermore, the advanced cooling system prevents overheating, ensuring smoother functioning across extended production shifts.

Ideal Uses

- Vacuum forming

- Degassing & drying

- Distillation & filtration

- Chemical processing

- Packaging machinery

- Laboratory applications

SINGLE STAGE

| Model No. | Max Vacuum | Approx Oil Filling Ltrs. | Free Air Displacement Lt./min, c.f.m, m3/hr | Drive Motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 I | 0.05 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 I | 0.05 mbar | 2 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.25 | ||

| JDO-150 I | 0.05 mbar | 3 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 0.50 | ||

| JDO-300 I | 0.05 mbar | 5 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.00 | ||

| JDO-500 I | 0.05 mbar | 9 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 1.50 | ||

| JDO-750 I | 0.05 mbar | 10 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 2.00 | ||

| JDO-1000 I | 0.05 mbar | 10 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 2.00 | ||

| JDO-1500 I | 0.05 mbar | 25 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 3.00 | ||

| JDO-2000 I | 0.05 mbar | 25 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 3.00 | ||

| JDO-3000 I | 0.05 mbar | 32 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 5.00 | ||

| JDO-5000 I | 0.05 mbar | 36 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 7.50 | ||

| JDO-7500 I | 0.05 mbar | 60 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 10.00 | ||

| JDO-10000 I | 0.05 mbar | 66 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 15.00 | ||

| JDO-15000 I | 0.05 mbar | 68 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 22.00 | ||

| JDO-20000 I | 0.05 mbar | 70 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 25.00 | ||

DOUBLE STAGE

| Model No. | max vacuum | approx oil filling ltrs. | free air displacement Lt./min, c.f.m, m3/hr | drive motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 II | 0.005 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 II | 0.005 mbar | 3 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.50 | ||

| JDO-150 II | 0.005 mbar | 4 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 1.00 | ||

| JDO-300 II | 0.005 mbar | 7 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.50 | ||

| JDO-500 II | 0.005 mbar | 12 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 2.00 | ||

| JDO-750 II | 0.005 mbar | 14 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 3.00 | ||

| JDO-1000 II | 0.005 mbar | 15 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 3.00 | ||

| JDO-1500 II | 0.005 mbar | 30 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 5.00 | ||

| JDO-2000 II | 0.005 mbar | 35 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 5.00 | ||

| JDO-3000 II | 0.005 mbar | 40 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 7.00 | ||

| JDO-5000 II | 0.005 mbar | 42 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 10.00 | ||

| JDO-7500 II | 0.005 mbar | 65 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 15.00 | ||

| JDO-10000 II | 0.005 mbar | 75 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 20.00 | ||

| JDO-15000 II | 0.005 mbar | 80 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 25.00 | ||

| JDO-20000 II | 0.005 mbar | 80 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 30.00 | ||

Field Application

- Laboratory Application of Chemical Plant.

- R&D Centre Vacuum Impregnation, Packing

- Vacuum Drying, Forming, Coating

- Lamp Industries, Leak Detection,

- Cryogenics, Distillation.Re-refining of oil

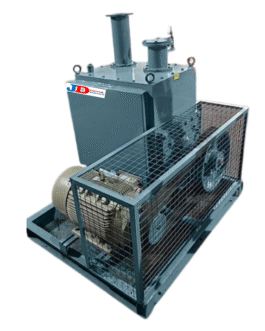

Capacity

- Max. Capacity: 50 LPM to 20,000 LPM (3.06 M3/hr.to 1204 M3/hr.)

- Max. Vacuum: Single Stage: 0.05 mm of Hg.

- Max. Vacuum: Two Stage: 0.005 mm of Hg.

- Recommend Motor: 0.25 HP to 25 HP, 1450 RPM Pump Speed: 500 RPM

Salient Features

- Robust Construction

- Compact, well-designed, and low-weight model

- Maximum Efficiency

- Trouble-free operation

- R&Easy and fast arrangement to change oil

- Thoroughly tested for seamless operation

- Easily handle dust-laden gases

- Built-in anti suck facility to prevent back of oil