ISO 9001 : 2015

Product categories

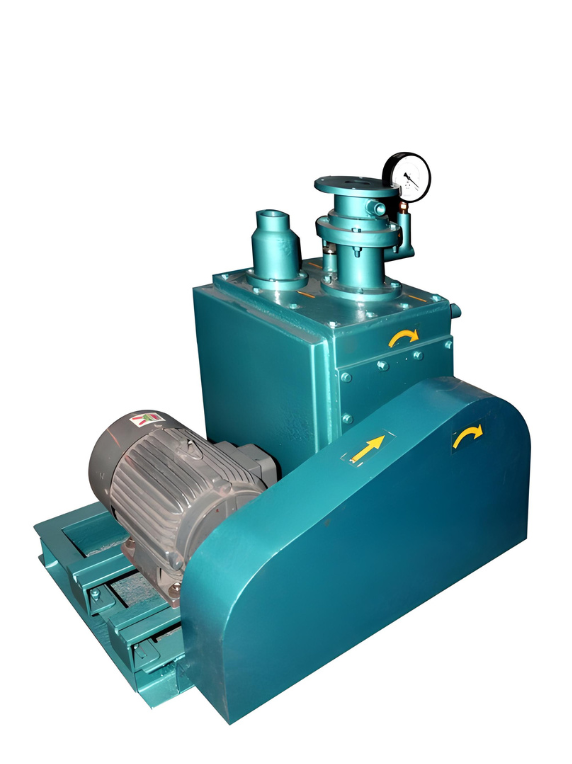

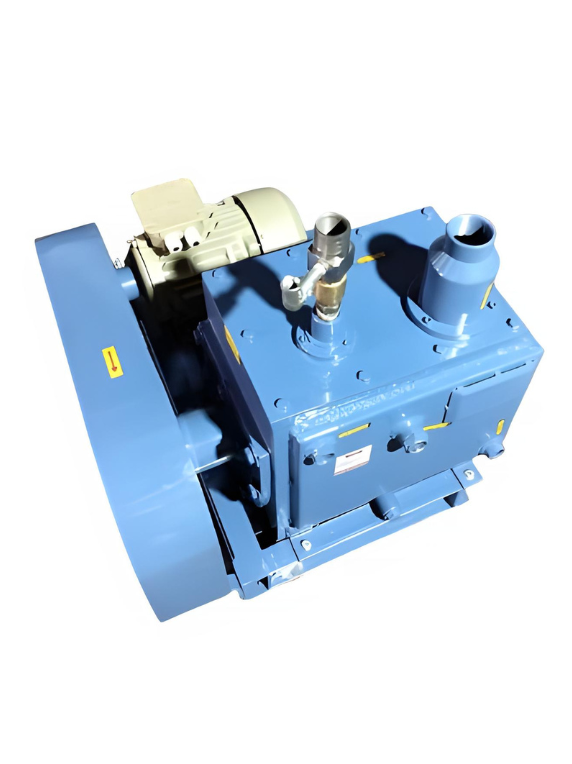

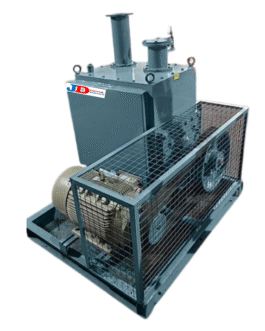

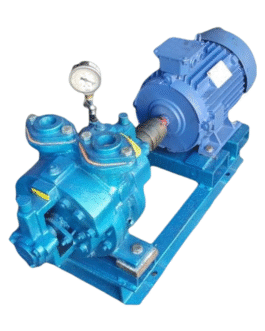

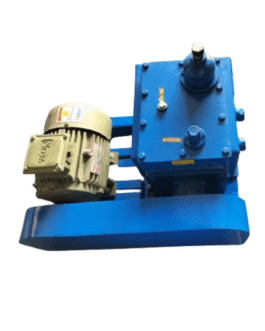

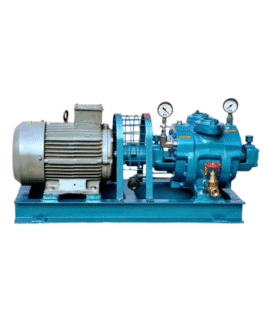

2000 LPM Rotary Vane Pump Double Stage Vacuum Pump

₹23,800

2000 LPM Rotary Vane Pump Double Stage Vacuum Pump - OIL SEAL VACUUM PUMP, Max Flow Rate: 2000 LPM, 5 HP: Capacity: 120 m3/hr, Voltage: 240 V, Air Cooled System.

- Pump Type: 2000 LPM Rotary Vane Pump Double Stage Vacuum Pump

- Flow Capacity: 2000 LPM (≈ 120 m³/hr)

- Ultimate Vacuum: Up to 0.05 mbar (approx. 29.9 inHg)

- Recommended Motor Power: 5 HP (depending on setup)

- Cooling System: Air / Water-cooled (optional)

- Lubrication: Oil-Sealed for enhanced sealing

- Noise Level: Low-noise, <70 dB

- Applications: Packaging, Pharma, Plastics, Labs, Food Processing

- Country of Origin: Made in India

Description

High-Performance 2000 LPM Rotary Vane Pump – Double Stage Vacuum Excellence

Experience industrial-grade suction power and reliability with the 2000 LPM Rotary Vane Double Stage Vacuum Pump. It is engineered for demanding vacuum applications that require consistent performance. With a high flow rate and long-term durability, this pump meets industry needs. This heavy-duty vacuum pump is designed to deliver a powerful 2000 liters per minute. Thus, it ensures maximum efficiency for manufacturing, laboratory, and processing industries.

With its precision-built double-stage mechanism, it guarantees deep vacuum levels while maintaining smooth, quiet, and stable operation.

This vacuum pump is a perfect combination of advanced engineering, robust construction, and superior oil-sealed technology. This ensures reduced maintenance and extended equipment lifespan.

Precision Engineering for Superior Vacuum Performance

The 2000 LPM Rotary Vane Pump is designed with dual-stage compression technology. This enables it to achieve higher vacuum levels and faster evacuation rates compared to single-stage models. Its balanced rotary vanes provide consistent airflow and minimize pulsation. This results in smoother operation. It is ideal for pharmaceutical production, food packaging, coating systems, vacuum furnaces, and industrial research setups.

Every component of this pump — from its oil-sealed chamber to the precision-machined rotor — is crafted for performance stability. It ensures airtight sealing and optimal oil circulation for low wear and superior reliability.

Durability, Low Maintenance & Energy Efficiency

Designed for continuous operation, the 2000 LPM Double Stage Vacuum Pump integrates heavy-duty bearings, high-grade vanes, and corrosion-resistant materials. It offers exceptional durability even under extreme conditions. Its low-noise and vibration design improves workplace comfort, while its energy-efficient motor reduces power consumption. As a result, this leads to lower operating costs.

The easy-access oil drain and inspection ports simplify maintenance, ensuring minimal downtime. Whether used in industrial production lines or vacuum forming systems, this pump is engineered to perform efficiently for years. It requires minimal service intervention.

Trusted for Industrial & Scientific Applications

From vacuum impregnation to laboratory analysis and industrial drying systems, this 2000 LPM Rotary Vane Vacuum Pump offers versatility. It adapts to a wide range of applications. Its robust double-stage design provides both high flow capacity and deep vacuum. Thus, it is a top choice for engineers and technicians seeking dependable performance and consistent results.

This is not just a pump — it’s a powerful, precision-engineered solution for businesses that demand quality, reliability, and efficiency in every process.

SINGLE STAGE

| Model No. | Max Vacuum | Approx Oil Filling Ltrs. | Free Air Displacement Lt./min, c.f.m, m3/hr | Drive Motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 I | 0.05 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 I | 0.05 mbar | 2 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.25 | ||

| JDO-150 I | 0.05 mbar | 3 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 0.50 | ||

| JDO-300 I | 0.05 mbar | 5 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.00 | ||

| JDO-500 I | 0.05 mbar | 9 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 1.50 | ||

| JDO-750 I | 0.05 mbar | 10 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 2.00 | ||

| JDO-1000 I | 0.05 mbar | 10 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 2.00 | ||

| JDO-1500 I | 0.05 mbar | 25 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 3.00 | ||

| JDO-2000 I | 0.05 mbar | 25 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 3.00 | ||

| JDO-3000 I | 0.05 mbar | 32 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 5.00 | ||

| JDO-5000 I | 0.05 mbar | 36 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 7.50 | ||

| JDO-7500 I | 0.05 mbar | 60 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 10.00 | ||

| JDO-10000 I | 0.05 mbar | 66 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 15.00 | ||

| JDO-15000 I | 0.05 mbar | 68 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 22.00 | ||

| JDO-20000 I | 0.05 mbar | 70 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 25.00 | ||

DOUBLE STAGE

| Model No. | max vacuum | approx oil filling ltrs. | free air displacement Lt./min, c.f.m, m3/hr | drive motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 II | 0.005 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 II | 0.005 mbar | 3 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.50 | ||

| JDO-150 II | 0.005 mbar | 4 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 1.00 | ||

| JDO-300 II | 0.005 mbar | 7 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.50 | ||

| JDO-500 II | 0.005 mbar | 12 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 2.00 | ||

| JDO-750 II | 0.005 mbar | 14 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 3.00 | ||

| JDO-1000 II | 0.005 mbar | 15 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 3.00 | ||

| JDO-1500 II | 0.005 mbar | 30 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 5.00 | ||

| JDO-2000 II | 0.005 mbar | 35 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 5.00 | ||

| JDO-3000 II | 0.005 mbar | 40 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 7.00 | ||

| JDO-5000 II | 0.005 mbar | 42 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 10.00 | ||

| JDO-7500 II | 0.005 mbar | 65 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 15.00 | ||

| JDO-10000 II | 0.005 mbar | 75 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 20.00 | ||

| JDO-15000 II | 0.005 mbar | 80 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 25.00 | ||

| JDO-20000 II | 0.005 mbar | 80 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 30.00 | ||

Field Application

- Laboratory Application of Chemical Plant.

- R&D Centre Vacuum Impregnation, Packing

- Vacuum Drying, Forming, Coating

- Lamp Industries, Leak Detection,

- Cryogenics, Distillation.Re-refining of oil

Capacity

- Max. Capacity: 50 LPM to 20,000 LPM (3.06 M3/hr.to 1204 M3/hr.)

- Max. Vacuum: Single Stage: 0.05 mm of Hg.

- Max. Vacuum: Two Stage: 0.005 mm of Hg.

- Recommend Motor: 0.25 HP to 25 HP, 1450 RPM Pump Speed: 500 RPM

Salient Features

- Robust Construction

- Compact, well-designed, and low-weight model

- Maximum Efficiency

- Trouble-free operation

- R&Easy and fast arrangement to change oil

- Thoroughly tested for seamless operation

- Easily handle dust-laden gases

- Built-in anti suck facility to prevent back of oil