ISO 9001 : 2015

Product categories

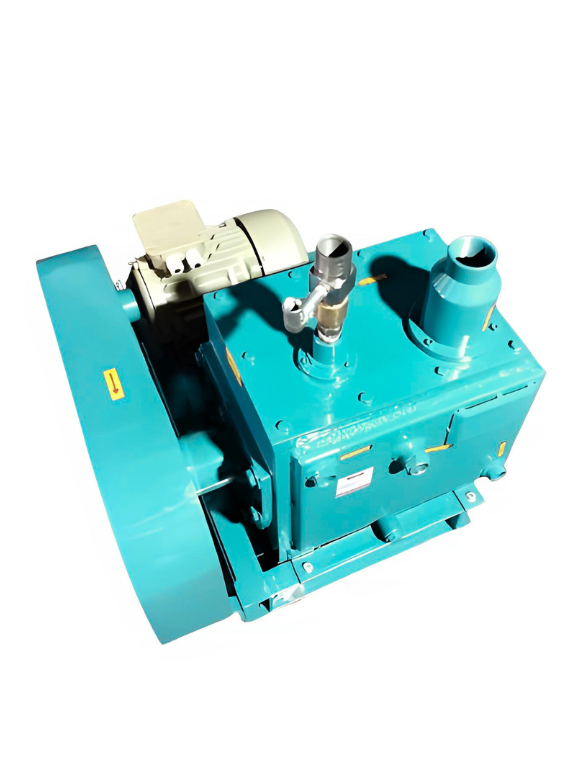

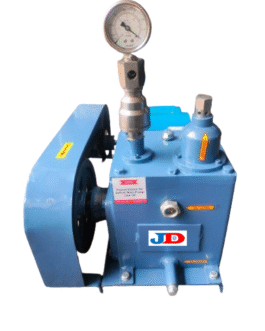

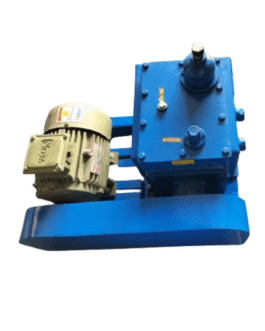

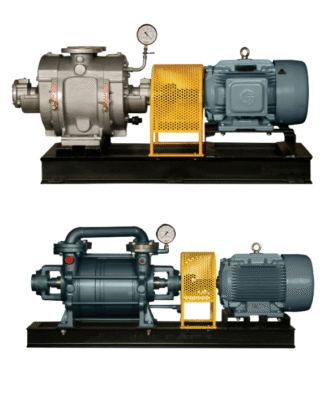

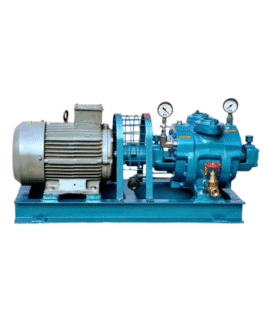

Laboratory Oil Sealed High Vacuum Pump

₹14,800

Discover the high-performance Laboratory Oil Sealed High Vacuum Pump by JD Vacuum Service, delivering 0.001 mbar ultra-deep vacuum, smooth operation, and exceptional durability for advanced laboratory and research applications. Optimize accuracy and reliability with this premium vacuum solution.

- Type: Oil Sealed High Vacuum Pump

- Capacity: Options range from 50 LPM to 500 LPM (customizable)

- Ultimate Vacuum: Up to 0.001 mbar

- Motor Power: 0.5 HP – 5 HP, depending on model

- Cooling System: Air-cooled / Water-cooled as per requirement

- Oil Capacity: Model dependent, ensuring optimal lubrication

- Material: Heavy-duty cast iron / high-grade alloy

- Noise Level: Low-vibration, low-noise operation

- Application Areas: R&D labs, chemical processing, electronics, vacuum filtration, degassing, coating systems

Description

Laboratory Oil Sealed High Vacuum Pump – JD Vacuum Service

Experience unmatched vacuum stability with the Laboratory Oil Sealed High Vacuum Pump from JD Vacuum Service. This pump is engineered for researchers and professionals who need consistent, deep vacuum levels. Moreover, its oil sealed mechanism ensures minimal leakage and maximum efficiency.

As a result, it is a trusted solution for scientific laboratories, R&D units, and industrial testing environments. Designed with high grade components, this pump delivers exceptional performance even during prolonged operations.

Advanced Engineering with Durable, High-Efficiency Components

Built to withstand rigorous laboratory workloads, this vacuum pump features a robust oil circulation system. This system enhances cooling, reduces wear, and extends operational life. Additionally, the precision engineered rotor and stator assembly boosts pumping speed while maintaining whisper quiet functionality. Because of its reliable sealing technology, users benefit from consistently high vacuum levels and reduced maintenance intervals. This results in superior long-term value.

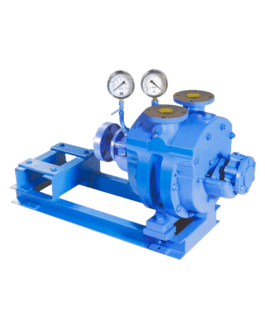

Reliable, Energy-Efficient & Easy-to-Maintain Design

This oil-sealed vacuum pump is crafted to provide effortless performance with minimal upkeep. Furthermore, its ergonomic design simplifies installation, oil monitoring, and routine servicing. As a result, laboratories experience reduced downtime and improved workflow efficiency. Whether for continuous operation or intermittent lab tasks, this pump ensures peak performance without compromising energy consumption.

Why This Vacuum Pump Is the Ideal Choice

Choosing the JD Vacuum Service Laboratory Oil Sealed Vacuum Pump means selecting precision, longevity, and high efficiency. In addition, the pump’s dependable construction and superior sealing technology ensure stable results across a broad range of laboratory applications. It is the perfect blend of durability, performance, and cost effectiveness—making it a smart investment for any research facility.

SINGLE STAGE

| Model No. | Max Vacuum | Approx Oil Filling Ltrs. | Free Air Displacement Lt./min, c.f.m, m3/hr | Drive Motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 I | 0.05 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 I | 0.05 mbar | 2 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.25 | ||

| JDO-150 I | 0.05 mbar | 3 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 0.50 | ||

| JDO-300 I | 0.05 mbar | 5 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.00 | ||

| JDO-500 I | 0.05 mbar | 9 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 1.50 | ||

| JDO-750 I | 0.05 mbar | 10 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 2.00 | ||

| JDO-1000 I | 0.05 mbar | 10 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 2.00 | ||

| JDO-1500 I | 0.05 mbar | 25 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 3.00 | ||

| JDO-2000 I | 0.05 mbar | 25 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 3.00 | ||

| JDO-3000 I | 0.05 mbar | 32 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 5.00 | ||

| JDO-5000 I | 0.05 mbar | 36 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 7.50 | ||

| JDO-7500 I | 0.05 mbar | 60 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 10.00 | ||

| JDO-10000 I | 0.05 mbar | 66 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 15.00 | ||

| JDO-15000 I | 0.05 mbar | 68 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 22.00 | ||

| JDO-20000 I | 0.05 mbar | 70 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 25.00 | ||

DOUBLE STAGE

| Model No. | max vacuum | approx oil filling ltrs. | free air displacement Lt./min, c.f.m, m3/hr | drive motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 II | 0.005 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 II | 0.005 mbar | 3 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.50 | ||

| JDO-150 II | 0.005 mbar | 4 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 1.00 | ||

| JDO-300 II | 0.005 mbar | 7 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.50 | ||

| JDO-500 II | 0.005 mbar | 12 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 2.00 | ||

| JDO-750 II | 0.005 mbar | 14 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 3.00 | ||

| JDO-1000 II | 0.005 mbar | 15 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 3.00 | ||

| JDO-1500 II | 0.005 mbar | 30 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 5.00 | ||

| JDO-2000 II | 0.005 mbar | 35 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 5.00 | ||

| JDO-3000 II | 0.005 mbar | 40 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 7.00 | ||

| JDO-5000 II | 0.005 mbar | 42 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 10.00 | ||

| JDO-7500 II | 0.005 mbar | 65 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 15.00 | ||

| JDO-10000 II | 0.005 mbar | 75 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 20.00 | ||

| JDO-15000 II | 0.005 mbar | 80 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 25.00 | ||

| JDO-20000 II | 0.005 mbar | 80 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 30.00 | ||

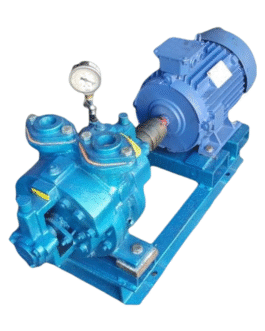

Field Application

- Laboratory Application of Chemical Plant.

- R&D Centre Vacuum Impregnation, Packing

- Vacuum Drying, Forming, Coating

- Lamp Industries, Leak Detection,

- Cryogenics, Distillation.Re-refining of oil

Capacity

- Max. Capacity: 50 LPM to 20,000 LPM (3.06 M3/hr.to 1204 M3/hr.)

- Max. Vacuum: Single Stage: 0.05 mm of Hg.

- Max. Vacuum: Two Stage: 0.005 mm of Hg.

- Recommend Motor: 0.25 HP to 25 HP, 1450 RPM Pump Speed: 500 RPM

Salient Features

- Robust Construction

- Compact, well-designed, and low-weight model

- Maximum Efficiency

- Trouble-free operation

- R&Easy and fast arrangement to change oil

- Thoroughly tested for seamless operation

- Easily handle dust-laden gases

- Built-in anti suck facility to prevent back of oil