ISO 9001 : 2015

CERTIFICATE COMPANY

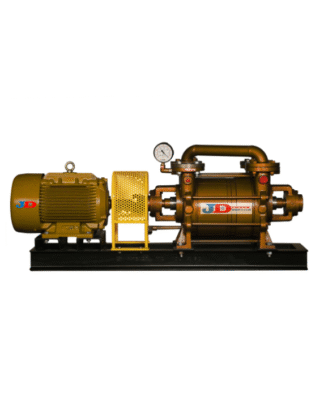

JDO 150 lpm oil seal vacuum pump

Belt Drive Rotary Vane Vacuum Pump JDO 150 LPM OIL SEAL VACUUM PUMP, Max Flow Rate: 150 LPM, 1 HP, Capacity: 9 m3/hr, Voltage: 240 V. Air Cooled System.

- Model Type: Oil Seal Vacuum Pump

- Suction Capacity: 150 LPM (≈ 9 m³/hr)

- Recommended Motor Power: 0.5 – 1 HP (depending on stage)

- Speed: 1440 / 2880 RPM

- Ultimate Vacuum: Up to 0.05 mbar (single stage) / 0.005 mbar (double stage)

- Cooling System: Air-cooled with efficient oil circulation

- Lubrication: Oil-sealed for smooth operation

- Construction: Cast iron / aluminum alloy housing with hardened steel rotor

- Operation Type: Continuous duty

Description

150 LPM Oil Seal Vacuum Pump

The 150 LPM Oil Seal Vacuum Pump is a reliable and high-performance solution designed for industrial and laboratory applications that require consistent vacuum generation. With a robust oil-sealed design, it ensures smooth operation, minimal wear, and long service life.

Key Features:

- Capacity: 150 Liters per Minute (LPM)

- Type: Oil Seal Vacuum Pump (single stage / double stage options available)

- Operation: Belt-drive / direct-drive configuration as per requirement

- Durability: Heavy-duty construction with high-grade materials for long-lasting performance

- Cooling: Efficient oil circulation system for continuous operation

- Vacuum Level: Capable of achieving a high degree of vacuum suitable for industrial and laboratory use

Applications:

- Packaging industry (vacuum sealing, forming, degassing)

- Chemical and pharmaceutical processing

- Laboratory experiments and research

- Food processing and preservation

- Vacuum impregnation and drying processes

This vacuum pump is engineered for high efficiency, low maintenance, and reliable operation, making it an ideal choice for industries that require dependable vacuum generation.

JDO SERIES

SINGLE STAGE

Vacuum Pump

| Model No. | Max Vacuum | Approx Oil Filling Ltrs. | Free Air Displacement Lt./min, c.f.m, m3/hr | Drive Motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 I | 0.05 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 I | 0.05 mbar | 2 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.25 | ||

| JDO-150 I | 0.05 mbar | 3 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 0.50 | ||

| JDO-300 I | 0.05 mbar | 5 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.00 | ||

| JDO-500 I | 0.05 mbar | 9 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 1.50 | ||

| JDO-750 I | 0.05 mbar | 10 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 2.00 | ||

| JDO-1000 I | 0.05 mbar | 10 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 2.00 | ||

| JDO-1500 I | 0.05 mbar | 25 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 3.00 | ||

| JDO-2000 I | 0.05 mbar | 25 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 3.00 | ||

| JDO-3000 I | 0.05 mbar | 32 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 5.00 | ||

| JDO-5000 I | 0.05 mbar | 36 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 7.50 | ||

| JDO-7500 I | 0.05 mbar | 60 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 10.00 | ||

| JDO-10000 I | 0.05 mbar | 66 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 15.00 | ||

| JDO-15000 I | 0.05 mbar | 68 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 22.00 | ||

| JDO-20000 I | 0.05 mbar | 70 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 25.00 | ||

JDO SERIES

DOUBLE STAGE

Vacuum Pump

| Model No. | max vacuum | approx oil filling ltrs. | free air displacement Lt./min, c.f.m, m3/hr | drive motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 II | 0.005 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 II | 0.005 mbar | 3 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.50 | ||

| JDO-150 II | 0.005 mbar | 4 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 1.00 | ||

| JDO-300 II | 0.005 mbar | 7 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.50 | ||

| JDO-500 II | 0.005 mbar | 12 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 2.00 | ||

| JDO-750 II | 0.005 mbar | 14 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 3.00 | ||

| JDO-1000 II | 0.005 mbar | 15 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 3.00 | ||

| JDO-1500 II | 0.005 mbar | 30 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 5.00 | ||

| JDO-2000 II | 0.005 mbar | 35 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 5.00 | ||

| JDO-3000 II | 0.005 mbar | 40 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 7.00 | ||

| JDO-5000 II | 0.005 mbar | 42 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 10.00 | ||

| JDO-7500 II | 0.005 mbar | 65 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 15.00 | ||

| JDO-10000 II | 0.005 mbar | 75 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 20.00 | ||

| JDO-15000 II | 0.005 mbar | 80 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 25.00 | ||

| JDO-20000 II | 0.005 mbar | 80 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 30.00 | ||