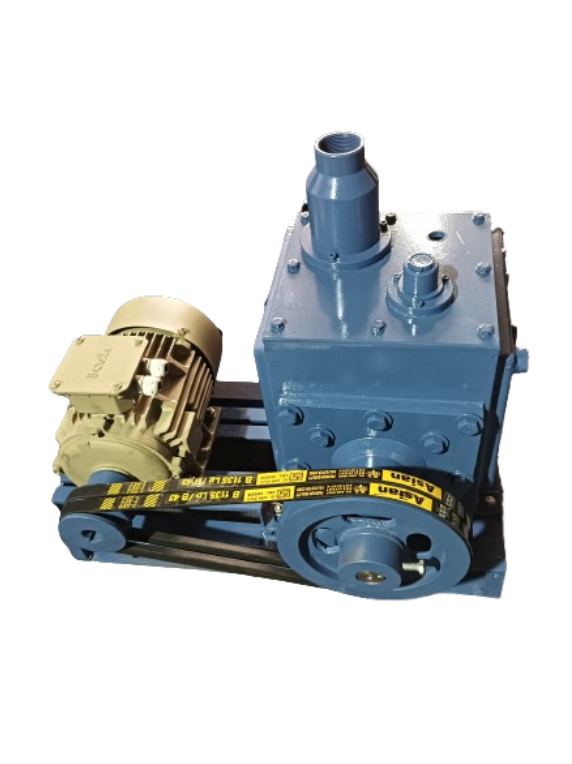

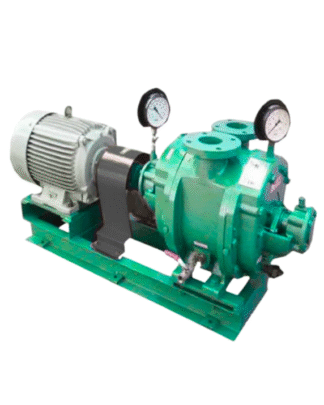

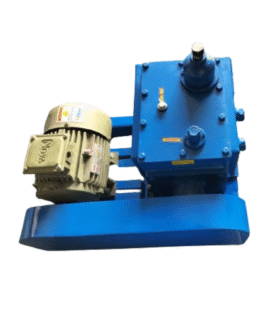

2 Stage Oil Sealed Rotary Vane Vacuum Pumps

ISO 9001 : 2015

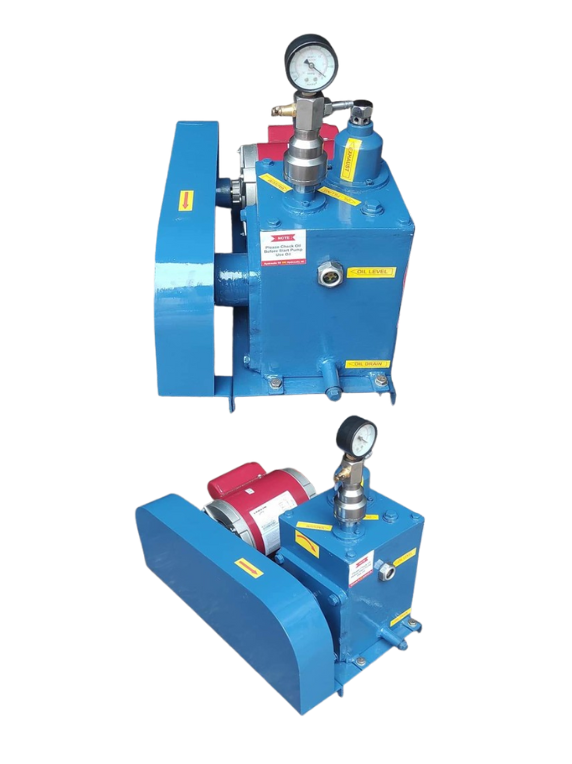

2 Stage Oil Sealed Rotary Vane Vacuum Pumps

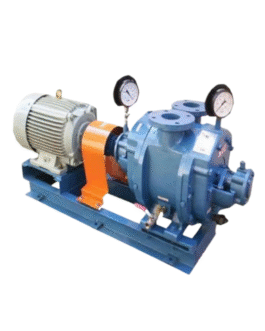

Experience unmatched deep vacuum performance with our 2-Stage Oil Sealed Rotary Vane Vacuum Pump. Designed for industrial and laboratory applications, it delivers fast evacuation, low noise, long-lasting durability, and exceptional reliability for demanding operations.

- Pump Type: 2 Stage Oil Sealed Rotary Vane

- Ultimate Vacuum: Up to 0.001 mbar / 1 micron (varies by model)

- Pumping Speed: Available from 20 LPM to 500 LPM (or higher on request)

- Motor Power: Ranges from 0.25 HP to 5 HP

- Displacement Speed: High-efficiency dual-stage compression

- Noise Level: Typically < 60–72 dB, depending on model

Description

Premium 2 Stage Oil Sealed Rotary Vane Vacuum Pumps

Experience superior vacuum efficiency with our 2 Stage Oil Sealed Rotary Vane Vacuum Pumps. They are engineered to deliver consistent deep vacuum levels for industrial, laboratory, and commercial environments. These pumps are designed to outperform standard single stage models.

They combine precision engineering with powerful dual-stage technology to achieve rapid evacuation, lower ultimate pressure, and stable long-term performance. Whether you’re supporting analytical instruments, packaging systems, or freeze drying equipment, this pump ensures smooth, reliable, and quiet operation—every time.

Durable, High-Quality Construction for Long-Lasting Reliability

Built with high-grade materials, our rotary vane vacuum pumps offer extended service life and outstanding durability. The oil-sealed mechanism minimizes wear. Thus, robust internal components reduce friction and heat generation, ensuring a longer lifespan with minimal maintenance. From heavy-duty bearings to corrosion-resistant vanes, every part is engineered to withstand continuous use in demanding environments. Enjoy peace of mind with equipment crafted for longevity, stability, and unmatched resilience.

Low Noise, Low Vibration & Maintenance-Friendly Design

Enhance your workspace with a pump designed for quiet operation, reduced vibration, and minimal service requirements. The integrated oil mist filter ensures cleaner exhaust. Meanwhile, the optimized airflow system enhances cooling for improved performance.

Easy access to service points allows for quick oil changes and routine checks, making upkeep simple even in fast paced industrial settings. With user friendly handling and an ergonomic, compact design, this pump is the ideal choice for both mobile and fixed installations.

Operational Features

- Cooling System: Air-cooled design for continuous duty

- Lubrication: Premium-grade vacuum pump oil with high thermal stability

- Oil Capacity: From 250 ml to 2.5 L, depending on pump size

- Inlet Port Size: 1/4″ to 1″ BSP/NPT (model specific)

- Exhaust System: Integrated oil mist filter for clean emissions

- Gas Ballast Valve: Included for handling moisture and vapor loads

- Anti-Suck Back Valve: Prevents oil backflow during shutdown

Construction & Design

- Housing Material: High-strength cast aluminum or cast iron

- Vanes: High-quality, wear resistant carbon vanes

- Rotational Speed: Typically 1,400–1,800 RPM

- Cooling Fins: Optimized design for improved thermal management

- Mounting: Rubber shock mounts for vibration reduction

SINGLE STAGE

| Model No. | Max Vacuum | Approx Oil Filling Ltrs. | Free Air Displacement Lt./min, c.f.m, m3/hr | Drive Motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 I | 0.05 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 I | 0.05 mbar | 2 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.25 | ||

| JDO-150 I | 0.05 mbar | 3 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 0.50 | ||

| JDO-300 I | 0.05 mbar | 5 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.00 | ||

| JDO-500 I | 0.05 mbar | 9 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 1.50 | ||

| JDO-750 I | 0.05 mbar | 10 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 2.00 | ||

| JDO-1000 I | 0.05 mbar | 10 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 2.00 | ||

| JDO-1500 I | 0.05 mbar | 25 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 3.00 | ||

| JDO-2000 I | 0.05 mbar | 25 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 3.00 | ||

| JDO-3000 I | 0.05 mbar | 32 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 5.00 | ||

| JDO-5000 I | 0.05 mbar | 36 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 7.50 | ||

| JDO-7500 I | 0.05 mbar | 60 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 10.00 | ||

| JDO-10000 I | 0.05 mbar | 66 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 15.00 | ||

| JDO-15000 I | 0.05 mbar | 68 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 22.00 | ||

| JDO-20000 I | 0.05 mbar | 70 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 25.00 | ||

DOUBLE STAGE

| Model No. | max vacuum | approx oil filling ltrs. | free air displacement Lt./min, c.f.m, m3/hr | drive motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 II | 0.005 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 II | 0.005 mbar | 3 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.50 | ||

| JDO-150 II | 0.005 mbar | 4 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 1.00 | ||

| JDO-300 II | 0.005 mbar | 7 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.50 | ||

| JDO-500 II | 0.005 mbar | 12 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 2.00 | ||

| JDO-750 II | 0.005 mbar | 14 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 3.00 | ||

| JDO-1000 II | 0.005 mbar | 15 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 3.00 | ||

| JDO-1500 II | 0.005 mbar | 30 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 5.00 | ||

| JDO-2000 II | 0.005 mbar | 35 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 5.00 | ||

| JDO-3000 II | 0.005 mbar | 40 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 7.00 | ||

| JDO-5000 II | 0.005 mbar | 42 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 10.00 | ||

| JDO-7500 II | 0.005 mbar | 65 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 15.00 | ||

| JDO-10000 II | 0.005 mbar | 75 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 20.00 | ||

| JDO-15000 II | 0.005 mbar | 80 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 25.00 | ||

| JDO-20000 II | 0.005 mbar | 80 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 30.00 | ||

Field Application

- Laboratory Application of Chemical Plant.

- R&D Centre Vacuum Impregnation, Packing

- Vacuum Drying, Forming, Coating

- Lamp Industries, Leak Detection,

- Cryogenics, Distillation.Re-refining of oil

Capacity

- Max. Capacity: 50 LPM to 20,000 LPM (3.06 M3/hr.to 1204 M3/hr.)

- Max. Vacuum: Single Stage: 0.05 mm of Hg.

- Max. Vacuum: Two Stage: 0.005 mm of Hg.

- Recommend Motor: 0.25 HP to 25 HP, 1450 RPM Pump Speed: 500 RPM

Salient Features

- Robust Construction

- Compact, well-designed, and low-weight model

- Maximum Efficiency

- Trouble-free operation

- R&Easy and fast arrangement to change oil

- Thoroughly tested for seamless operation

- Easily handle dust-laden gases

- Built-in anti suck facility to prevent back of oil