ISO 9001 : 2015

Product categories

- Air blowers (11)

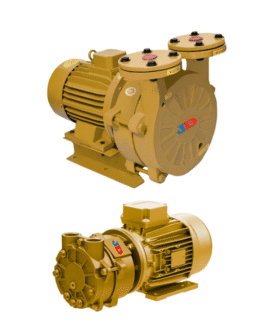

- DOUBLE STAGE VACUUM PUMP (55)

- Monoblock Vacuum Pumps (11)

- oil seal vacuum pumps (63)

- Roots Blowers (7)

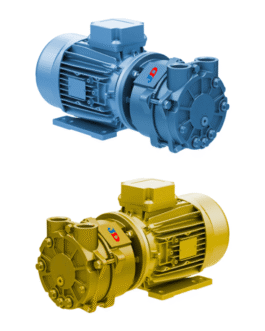

- Single Stage Vacuum Pumps (62)

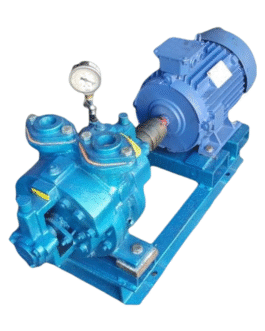

- Single Stage Watering Vacuum Pump (20)

- Two Stage Water Ring Vacuum Pumps (14)

- VACUUM PUMPS (63)

- water ring vacuum pumps (49)

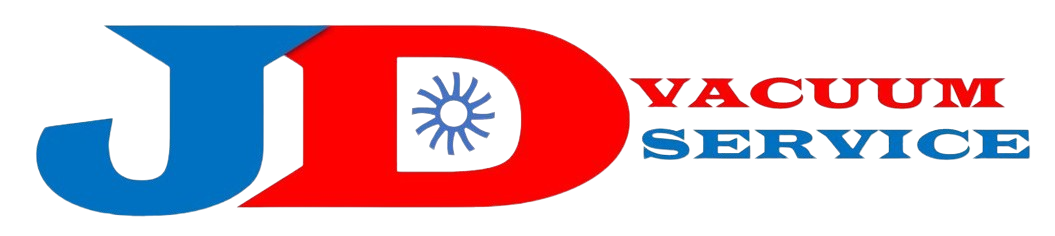

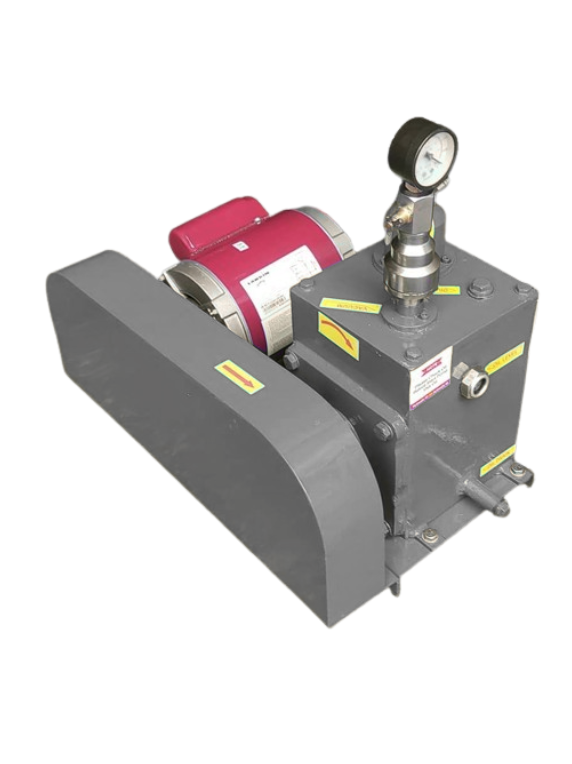

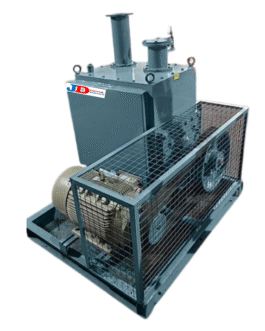

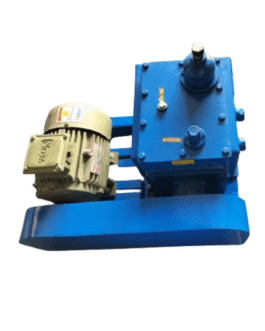

50 LPM Double Stage Oil Seal Vacuum Pump

At JD Vacuum Services, we pride ourselves on delivering high-performance vacuum solutions that combine innovation, reliability, and affordability. Our pumps are trusted by laboratories, industries, and research facilities across India and beyond for their unmatched performance and quality.

- Model: 50 LPM Double Stage

- Pumping Speed: 50 Liters per Minute

- Type: Oil Sealed Rotary Vane (Double Stage)

- Ultimate Vacuum: Up to 0.001 mbar

- Motor Power: 0.25 HP (approx.)

- Cooling Method: Air Cooled

- Lubrication: Oil Sealed System

- Inlet/Outlet Connections: Standard Fittings for Easy Integration

- Noise Level: Low (below 65 dB)

Description

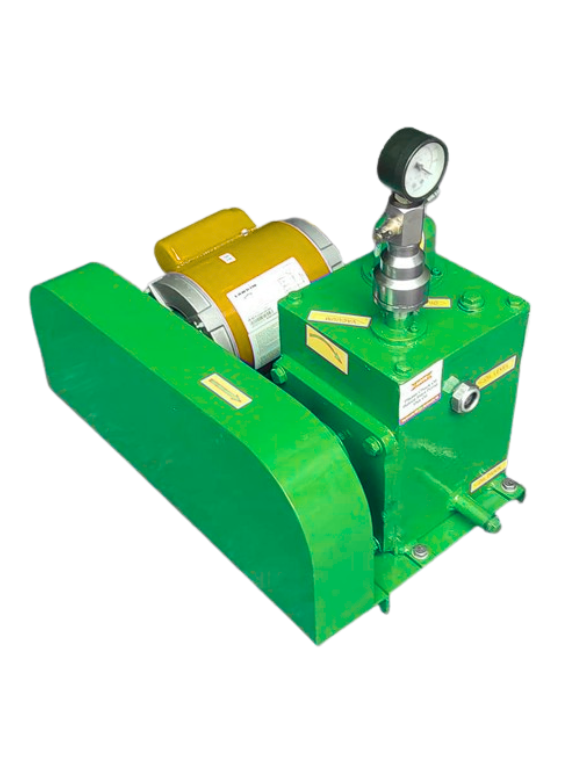

50 LPM Double Stage Oil Seal Vacuum Pump – High Performance for Demanding Industrial Applications

The 50 LPM Double Stage Oil Seal Vacuum Pump from JD Vacuum Service is engineered to deliver superior vacuum efficiency. It ensures stable, deep, and consistent vacuum levels across a wide range of industrial operations. With its double-stage design, this pump guarantees higher vacuum depth, lower noise, and improved performance—even under continuous duty conditions.

Whether you work in pharmaceuticals, laboratories, refrigeration servicing, packaging, or chemical processing, this pump provides the reliable suction power you need for precise results. This makes it an ideal choice for those in need of a 50 LPM Double Stage Oil Seal Vacuum Pump for critical operations.

Its 50 LPM pumping speed ensures faster evacuation, reducing downtime and improving productivity. The advanced oil-seal mechanism enhances sealing efficiency, minimizes vapor backflow, and ensures the long-term reliability that industries depend on.

Built for Durability, Stability & Long-Term Operation

This heavy-duty vacuum pump is crafted using high-quality cast iron, precision-machined components, and robust internal assemblies. Therefore, it is ideal for operations requiring continuous and stable vacuum performance. The internally oil-lubricated system, combined with a high-grade exhaust filter, reduces wear and maintains smooth running. These are characteristics of a top-notch 50 LPM Double Stage Oil Seal system.

The pump’s optimized cooling system prevents overheating, allowing it to function even during extended working hours. Additionally, its anti-corrosion coating, high-tolerance bearings, and vibration-free design make it perfect for harsh industrial environments.

Compact, User-Friendly & Energy-Efficient Design

Despite its powerful performance, this pump is compact, lightweight, and easy to install. Thus, it is suitable for laboratories and small industrial setups where space is limited. The low-noise motor, ergonomic design, and minimal maintenance requirement ensure a smooth user experience. Its enhanced energy-saving motor reduces power consumption while delivering maximum output, which are key considerations when selecting a 50 LPM Double Stage Oil Seal Vacuum Pump.

From leak testing to vacuum filtration, drying, distillation, freezing, and dehydration applications, this versatile unit supports a wide range of processes with outstanding reliability.

Why You Should Choose JD Vacuum Service

Customers trust JD Vacuum Service because every pump is precision-tested, performance-certified, and backed by reliable after-sales support. Quick service availability and guaranteed spare part supply further build trust. When you invest in this pump, you’re not just buying equipment; you’re bringing home efficiency, durability, and long-term peace of mind. Consider choosing the JD Vacuum Service 50 LPM Double Stage Oil Seal Vacuum Pump for unparalleled industrial results.

SINGLE STAGE

| Model No. | Max Vacuum | Approx Oil Filling Ltrs. | Free Air Displacement Lt./min, c.f.m, m3/hr | Drive Motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 I | 0.05 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 I | 0.05 mbar | 2 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.25 | ||

| JDO-150 I | 0.05 mbar | 3 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 0.50 | ||

| JDO-300 I | 0.05 mbar | 5 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.00 | ||

| JDO-500 I | 0.05 mbar | 9 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 1.50 | ||

| JDO-750 I | 0.05 mbar | 10 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 2.00 | ||

| JDO-1000 I | 0.05 mbar | 10 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 2.00 | ||

| JDO-1500 I | 0.05 mbar | 25 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 3.00 | ||

| JDO-2000 I | 0.05 mbar | 25 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 3.00 | ||

| JDO-3000 I | 0.05 mbar | 32 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 5.00 | ||

| JDO-5000 I | 0.05 mbar | 36 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 7.50 | ||

| JDO-7500 I | 0.05 mbar | 60 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 10.00 | ||

| JDO-10000 I | 0.05 mbar | 66 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 15.00 | ||

| JDO-15000 I | 0.05 mbar | 68 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 22.00 | ||

| JDO-20000 I | 0.05 mbar | 70 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 25.00 | ||

DOUBLE STAGE

| Model No. | max vacuum | approx oil filling ltrs. | free air displacement Lt./min, c.f.m, m3/hr | drive motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 II | 0.005 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 II | 0.005 mbar | 3 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.50 | ||

| JDO-150 II | 0.005 mbar | 4 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 1.00 | ||

| JDO-300 II | 0.005 mbar | 7 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.50 | ||

| JDO-500 II | 0.005 mbar | 12 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 2.00 | ||

| JDO-750 II | 0.005 mbar | 14 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 3.00 | ||

| JDO-1000 II | 0.005 mbar | 15 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 3.00 | ||

| JDO-1500 II | 0.005 mbar | 30 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 5.00 | ||

| JDO-2000 II | 0.005 mbar | 35 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 5.00 | ||

| JDO-3000 II | 0.005 mbar | 40 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 7.00 | ||

| JDO-5000 II | 0.005 mbar | 42 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 10.00 | ||

| JDO-7500 II | 0.005 mbar | 65 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 15.00 | ||

| JDO-10000 II | 0.005 mbar | 75 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 20.00 | ||

| JDO-15000 II | 0.005 mbar | 80 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 25.00 | ||

| JDO-20000 II | 0.005 mbar | 80 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 30.00 | ||

Field Application

- Laboratory Application of Chemical Plant.

- R&D Centre Vacuum Impregnation, Packing

- Vacuum Drying, Forming, Coating

- Lamp Industries, Leak Detection,

- Cryogenics, Distillation.Re-refining of oil

Capacity

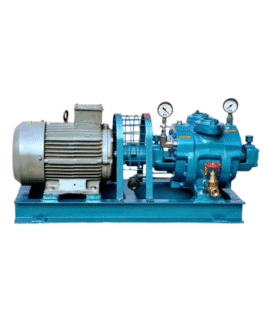

- Max. Capacity: 50 LPM to 20,000 LPM (3.06 M3/hr.to 1204 M3/hr.)

- Max. Vacuum: Single Stage: 0.05 mm of Hg.

- Max. Vacuum: Two Stage: 0.005 mm of Hg.

- Recommend Motor: 0.25 HP to 25 HP, 1450 RPM Pump Speed: 500 RPM

Salient Features

- Robust Construction

- Compact, well-designed, and low-weight model

- Maximum Efficiency

- Trouble-free operation

- R&Easy and fast arrangement to change oil

- Thoroughly tested for seamless operation

- Easily handle dust-laden gases

- Built-in anti suck facility to prevent back of oil