ISO 9001 : 2015

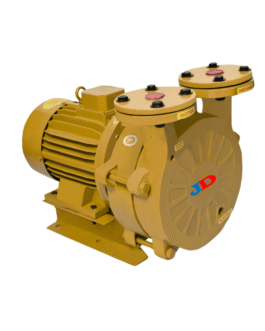

JDO 750 lpm oil seal vacuum pump

Belt Drive Rotary Vane Pumps JDO 750 LPM OIL SEAL VACUUM PUMP, Max Flow Rate: 750 LPM, 2 HP ; Capacity. 45 m3/hr ; Voltage. 240 V ; Air Cooled System.

- Model: JDO 750

- Pump Type: Oil Seal Rotary Vane

- Max. VACUUM: 0.005 (760 mm/Hg)

- Number of Stages: Single and Double

- Req. Motor: 2 HP and 3 HP

- Capacity: 750 LPM, 45 M3/HR, 26.5 CFM

Description

JDO 750 LPM Oil Seal Vacuum Pump – Precision, Power & Long-Life Performance

Unmatched Vacuum Performance for Heavy-Duty Industrial Needs

The JDO 750 LPM Oil Seal Vacuum Pump is engineered for industries that demand consistent vacuum levels, high flow capacity, and zero compromise on reliability. It delivers an impressive 750 liters per minute capacity. This pump ensures seamless operation in packaging, pharmaceuticals, process industries, chemical labs, and fabrication units. With its rugged construction and precision-balanced components, it offers exceptional durability. It performs well even in continuous 24/7 operations.

Whether you’re upgrading an existing system or designing a new production line, this pump guarantees enhanced productivity, stable vacuum output, and lower downtime. It is a cornerstone choice for industrial vacuum requirements.

Premium Build Quality & Long-Lasting Oil Seal Technology

Built with high-grade cast iron housing, the JDO 750 LPM Oil Seal Pump ensures superior protection against wear and temperature fluctuations. Its advanced oil seal mechanism keeps internal components perfectly lubricated. This reduces friction and extends pump lifespan dramatically.

The pump incorporates:

- High-efficiency rotor and vane assembly

- Optimized oil circulation system for cooler operation

- Low-noise engineering for quieter working environments

- Anti-rust and anti-corrosion internals for long-term performance

This combination of smart engineering and premium materials makes it a trusted solution for demanding industrial applications.

Cornerstone Features that Elevate Performance & Reliability

This model has been crafted to serve as a cornerstone asset in industrial vacuum systems, offering unmatched reliability and operational convenience.

Key Cornerstone Advantages:

- 750 LPM suction capacity for high-volume vacuum operations

- Ultimate vacuum level up to 0.05 mbar depending on application

- Thermally optimized design to prevent overheating

- Easy oil-fill and drainage ports for simplified maintenance

- Seamless integration with existing machinery and production lines

- Low vibration performance protecting nearby instruments and workers

Built for precision-critical tasks, the JDO 750 stands out as a dependable backbone for industrial processing, ensuring smoother operations, reduced maintenance frequency, and overall cost savings.

- Laboratory Application Of Chemical Plant

- Distillation

- Vacuum Drying

- Gas Charging

- R&D Center Vacuum Impregnation, Packing

- Forming Coating

- Relevant Recovery

- Re-refining of oil

- Dehydration

- Filtration Processes

- Thin Film Coating

- Vacuum Metallurgy

- Vacuum Sublimation

- Robust Construction

- Compact, well-designed and low weight model

- Maximum Efficiency

- Trouble-free operation

- R&Easy and fast arrangement to change oil

- Thoroughly tested for seamless operation

- Easily handle dust laded gases

- Built-in anti suck facility to prevent back of oil