laboratory vacuum pump Manufacturer from Ahmedabad

ISO 9001 : 2015

laboratory vacuum pump Manufacturer from Ahmedabad

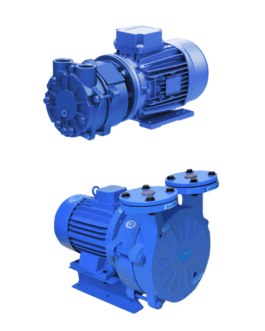

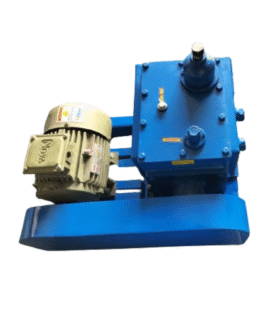

Get high-performance Laboratory Vacuum Pumps engineered for precision, durability, and low maintenance. Ideal for filtration, drying, and distillation. Choose trusted vacuum solutions for research and industry—built to last and perform with 99% efficiency.

- Type: Laboratory Vacuum Pump

- Stages: Single / Double stage (depending on model)

- Suction Capacity: Available in multiple ranges (from 50 LPM to 500 LPM or as per requirement)

- Ultimate Vacuum: Up to 760 mm Hg

- Motor Power: 0.25 HP to 10 HP (varies by model)

- Speed (RPM): 1440 / 2850 RPM

- Cooling Method: Air cooled / Water cooled

- Operation: Oil-sealed / Oil-free (optional based on model)

- Water Consumption: Approx. 5–10 LPM (for water ring types)

- Noise Level: Low-noise, vibration-free operation

- Applications: Filtration, drying, distillation, concentration, degassing, research and industrial use

Description

Vacuum Pump For Laboratory Application

Our laboratory vacuum pump is engineered to deliver consistent suction power, ensuring accuracy and reliability for critical scientific and industrial applications. Whether you are performing filtration, degassing, drying, distillation, or concentration tasks, this pump guarantees smooth operation with stable vacuum performance. Built for precision, it supports research facilities, chemical labs, and industrial testing units by offering steady results every time you need them.

Compact Design with High Efficiency

Designed with efficiency in mind, this lab vacuum pump combines a space-saving compact structure with powerful suction capacity. Its lightweight and durable build makes it easy to install and relocate without compromising performance. The low noise and vibration-free operation enhance the working environment, making it ideal for long laboratory hours. With minimal maintenance requirements, you save both time and operational costs.

Versatile and Durable for Long-Term Use

Crafted from premium-grade materials, this lab vacuum pump ensures long service life, chemical resistance, and durability even under continuous operation. It is highly versatile, suitable for applications in medical labs, educational institutes, pharmaceutical production, R&D centers, and industrial quality testing. Its robust design supports both small-scale experiments and heavy-duty laboratory processes, giving you unmatched flexibility and reliability.

Commitment to Quality and After-Sales Support

At JD Vacuum Service, we pride ourselves on offering more than just a product — we deliver a long-term vacuum solution. Each Laboratory Vacuum Pump is backed by a comprehensive warranty and supported by professional service technicians who understand laboratory challenges.

We provide:

- Installation guidance and training for lab staff.

- Regular maintenance plans to extend pump life.

- Spare parts availability for quick replacements.

- Technical consultation for process optimization.

Our commitment to quality, reliability, and customer satisfaction has made us one of the leading vacuum pump manufacturers and suppliers in India. When you invest in our laboratory vacuum pumps, you invest in precision, trust, and long-lasting performance.

SINGLE STAGE

| Model No. | Max Vacuum | Approx Oil Filling Ltrs. | Free Air Displacement Lt./min, c.f.m, m3/hr | Drive Motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 I | 0.05 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 I | 0.05 mbar | 2 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.25 | ||

| JDO-150 I | 0.05 mbar | 3 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 0.50 | ||

| JDO-300 I | 0.05 mbar | 5 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.00 | ||

| JDO-500 I | 0.05 mbar | 9 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 1.50 | ||

| JDO-750 I | 0.05 mbar | 10 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 2.00 | ||

| JDO-1000 I | 0.05 mbar | 10 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 2.00 | ||

| JDO-1500 I | 0.05 mbar | 25 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 3.00 | ||

| JDO-2000 I | 0.05 mbar | 25 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 3.00 | ||

| JDO-3000 I | 0.05 mbar | 32 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 5.00 | ||

| JDO-5000 I | 0.05 mbar | 36 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 7.50 | ||

| JDO-7500 I | 0.05 mbar | 60 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 10.00 | ||

| JDO-10000 I | 0.05 mbar | 66 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 15.00 | ||

| JDO-15000 I | 0.05 mbar | 68 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 22.00 | ||

| JDO-20000 I | 0.05 mbar | 70 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 25.00 | ||

DOUBLE STAGE

| Model No. | max vacuum | approx oil filling ltrs. | free air displacement Lt./min, c.f.m, m3/hr | drive motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 II | 0.005 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 II | 0.005 mbar | 3 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.50 | ||

| JDO-150 II | 0.005 mbar | 4 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 1.00 | ||

| JDO-300 II | 0.005 mbar | 7 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.50 | ||

| JDO-500 II | 0.005 mbar | 12 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 2.00 | ||

| JDO-750 II | 0.005 mbar | 14 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 3.00 | ||

| JDO-1000 II | 0.005 mbar | 15 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 3.00 | ||

| JDO-1500 II | 0.005 mbar | 30 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 5.00 | ||

| JDO-2000 II | 0.005 mbar | 35 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 5.00 | ||

| JDO-3000 II | 0.005 mbar | 40 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 7.00 | ||

| JDO-5000 II | 0.005 mbar | 42 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 10.00 | ||

| JDO-7500 II | 0.005 mbar | 65 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 15.00 | ||

| JDO-10000 II | 0.005 mbar | 75 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 20.00 | ||

| JDO-15000 II | 0.005 mbar | 80 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 25.00 | ||

| JDO-20000 II | 0.005 mbar | 80 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 30.00 | ||