ISO 9001 : 2015

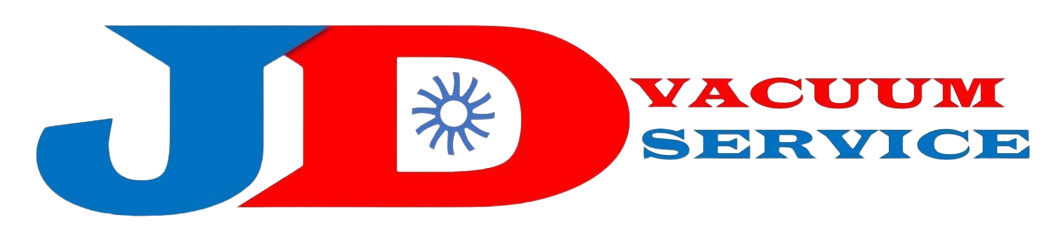

Oil Ring High Vacuum Pump

Experience powerful and consistent suction with the Oil Ring High Vacuum Pump from JD Vacuum Service. Engineered for durability, energy efficiency, and deep vacuum performance, this pump delivers high-level reliability across more than 10 industrial applications. Ideal for chemical, pharmaceutical, and processing industries.

- Type: Oil Ring High Vacuum Pump

- Model Options: Available in multiple capacities (customizable)

- Ultimate Vacuum: Up to 0.1 mmHg depending on model

- Pump Speed: Ranges from 50–500 LPM

- Power Requirement: 0.5 HP to 10 HP (as per model)

- Cooling System: Air-cooled / Water-cooled options

- Construction Material: Cast iron / Stainless steel variants

- Lubrication: Oil-sealed, continuous feed

- Noise Level: Low-noise operation < 65 dB

- Applications: Chemical, Pharma, Food, Metallurgy, R&D labs, Packaging

Description

Oil Ring High Vacuum Pump – JD Vacuum Service

The Oil Ring High Vacuum Pump from JD Vacuum Service is engineered to deliver exceptional vacuum levels. It is the perfect solution for industries that rely on precise and continuous operations. Thanks to its robust oil-sealed mechanism, it achieves deep vacuum performance while maintaining outstanding stability. Moreover, the pump’s precision-engineered components ensure minimal vibration and quiet operation.

This allows businesses to operate efficiently without unwanted interruptions. As a result, this pump becomes an essential asset for laboratories, production units, research facilities, and processing plants seeking long-term reliability.

Durable Construction & Energy-Efficient Operation

Built with heavy-duty materials, the Oil Ring High Vacuum Pump provides long operational life even under challenging working conditions. Additionally, its advanced lubrication system reduces internal wear and significantly lowers maintenance requirements. This not only enhances durability but also ensures energy-efficient performance, ultimately reducing operational costs. Furthermore, the compact and user-friendly design allows for easy installation, making it ideal for both small and large-scale setups.

Versatile Use Across Multiple Industries

Designed for versatility, this vacuum pump supports operations in chemical processing, pharmaceuticals, packaging, food processing, metallurgy, and more. Because it maintains consistent vacuum pressure, it becomes suitable for moisture removal, degassing, drying, and filtration applications. Moreover, its ability to handle both light and heavy-duty tasks makes it a trusted choice across industries. In these industries, precision and reliability are non-negotiable.

SINGLE STAGE

| Model No. | Max Vacuum | Approx Oil Filling Ltrs. | Free Air Displacement Lt./min, c.f.m, m3/hr | Drive Motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 I | 0.05 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 I | 0.05 mbar | 2 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.25 | ||

| JDO-150 I | 0.05 mbar | 3 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 0.50 | ||

| JDO-300 I | 0.05 mbar | 5 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.00 | ||

| JDO-500 I | 0.05 mbar | 9 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 1.50 | ||

| JDO-750 I | 0.05 mbar | 10 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 2.00 | ||

| JDO-1000 I | 0.05 mbar | 10 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 2.00 | ||

| JDO-1500 I | 0.05 mbar | 25 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 3.00 | ||

| JDO-2000 I | 0.05 mbar | 25 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 3.00 | ||

| JDO-3000 I | 0.05 mbar | 32 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 5.00 | ||

| JDO-5000 I | 0.05 mbar | 36 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 7.50 | ||

| JDO-7500 I | 0.05 mbar | 60 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 10.00 | ||

| JDO-10000 I | 0.05 mbar | 66 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 15.00 | ||

| JDO-15000 I | 0.05 mbar | 68 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 22.00 | ||

| JDO-20000 I | 0.05 mbar | 70 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 25.00 | ||

DOUBLE STAGE

| Model No. | max vacuum | approx oil filling ltrs. | free air displacement Lt./min, c.f.m, m3/hr | drive motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 II | 0.005 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 II | 0.005 mbar | 3 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.50 | ||

| JDO-150 II | 0.005 mbar | 4 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 1.00 | ||

| JDO-300 II | 0.005 mbar | 7 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.50 | ||

| JDO-500 II | 0.005 mbar | 12 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 2.00 | ||

| JDO-750 II | 0.005 mbar | 14 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 3.00 | ||

| JDO-1000 II | 0.005 mbar | 15 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 3.00 | ||

| JDO-1500 II | 0.005 mbar | 30 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 5.00 | ||

| JDO-2000 II | 0.005 mbar | 35 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 5.00 | ||

| JDO-3000 II | 0.005 mbar | 40 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 7.00 | ||

| JDO-5000 II | 0.005 mbar | 42 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 10.00 | ||

| JDO-7500 II | 0.005 mbar | 65 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 15.00 | ||

| JDO-10000 II | 0.005 mbar | 75 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 20.00 | ||

| JDO-15000 II | 0.005 mbar | 80 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 25.00 | ||

| JDO-20000 II | 0.005 mbar | 80 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 30.00 | ||

Field Application

- Laboratory Application of Chemical Plant.

- R&D Centre Vacuum Impregnation, Packing

- Vacuum Drying, Forming, Coating

- Lamp Industries, Leak Detection,

- Cryogenics, Distillation.Re-refining of oil

Capacity

- Max. Capacity: 50 LPM to 20,000 LPM (3.06 M3/hr.to 1204 M3/hr.)

- Max. Vacuum: Single Stage: 0.05 mm of Hg.

- Max. Vacuum: Two Stage: 0.005 mm of Hg.

- Recommend Motor: 0.25 HP to 25 HP, 1450 RPM Pump Speed: 500 RPM

Salient Features

- Robust Construction

- Compact, well-designed, and low-weight model

- Maximum Efficiency

- Trouble-free operation

- R&Easy and fast arrangement to change oil

- Thoroughly tested for seamless operation

- Easily handle dust-laden gases

- Built-in anti suck facility to prevent back of oil