ISO 9001 : 2015

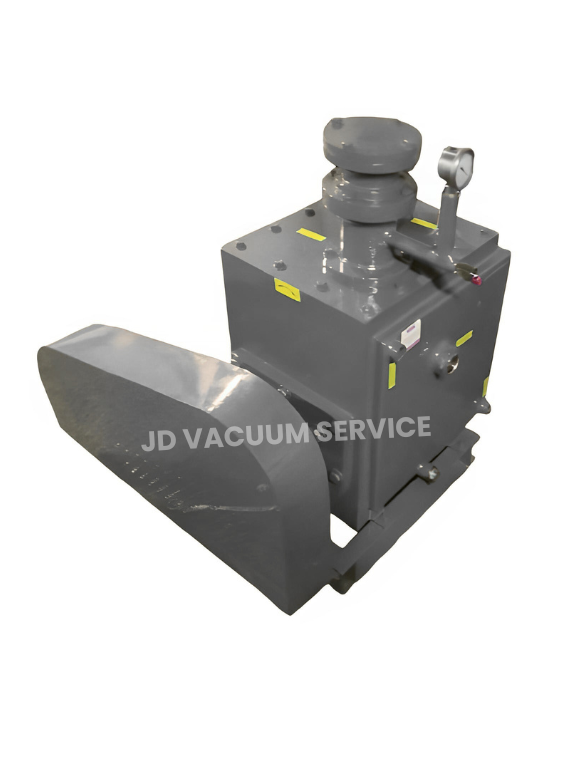

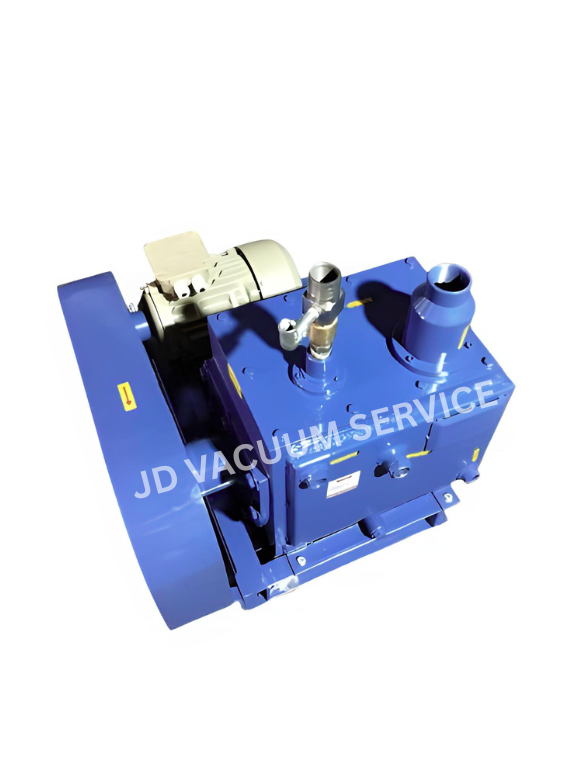

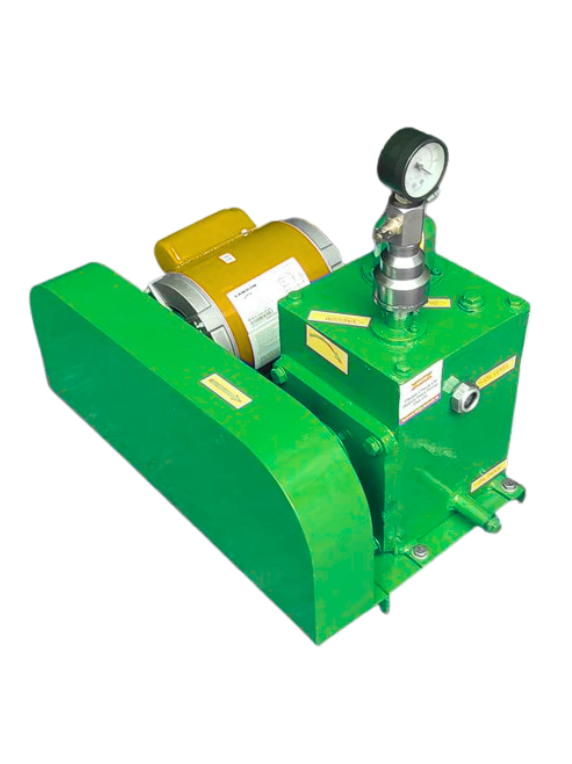

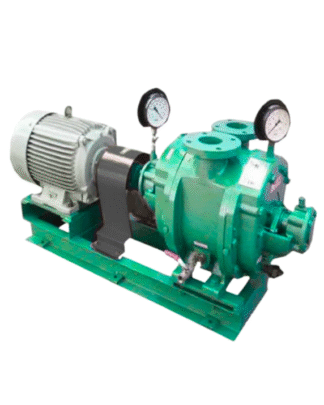

SV 150 Double Stage Vacuum Pump

Boost efficiency with the SV 150 Double Stage Vacuum Pump—an advanced 2-stage vacuum system designed for laboratories and industrial use. Enjoy powerful suction, quiet operation, and long-lasting durability for flawless performance in every application.

- Model: SV 150

- Pump Type: Oil-Lubricated Double Stage Vacuum Pump

- Free Air Displacement: 150 LPM (approx.)

- Ultimate Vacuum: Up to 0.001 mbar (Two-Stage High Vacuum)

- Motor Power: 0.75 HP / 0.55 kW (customizable as required)

- Cooling Method: Air-cooled with enhanced heat dissipation fins

- Noise Level: Low-noise operation (approx. 55–60 dB)

- Construction Material: Heavy-duty cast aluminum body

- Lubrication System: Splash lubrication for longer life

- Weight: 18–25 kg (varies by configuration)

- Dimensions: Compact footprint for easy installation

- Duty Cycle: Suitable for continuous operation

- Recommended Oil Type: High-grade vacuum pump oil ISO-VG 68

Description

SV 150 Double Stage Vacuum Pump – High Performance, Precision & Reliability

Unlock powerful and stable vacuum output with the SV 150 Double Stage Vacuum Pump. Engineered for laboratories, industrial processes, and research facilities, this pump delivers superior vacuum depth thanks to its efficient two-stage mechanism. Its advanced dual-chamber design enhances gas removal, minimizes pulsation, and ensures consistent performance even during long continuous operation. Whether you’re running sensitive analytical instruments or large-scale production systems, this pump offers flawless vacuum stability every time.

Engineered for Durability & Long Service Life

Built from premium grade materials, the SV 150 is designed to withstand demanding environments with ease. Its heavy-duty construction ensures resistance to wear, corrosion, and high operating temperatures. Smooth running internal components reduce friction and extend service intervals, making it an ideal choice for laboratories and industries seeking reliable, maintenance friendly equipment. With proper care, this pump performs flawlessly for years, offering outstanding cost efficiency and operational dependability.

Quiet, Efficient & User-Friendly Operation

Experience a vacuum pump that balances power with quiet, vibration free performance. The SV 150 is optimized for low noise output, ensuring a pleasant and interruption-free working environment.

Its compact footprint and streamlined design make installation simple, while the easy-access maintenance points help users perform routine checks quickly.

From research labs to manufacturing units, its ease of use makes it a top choice for professionals who value both performance and convenience.

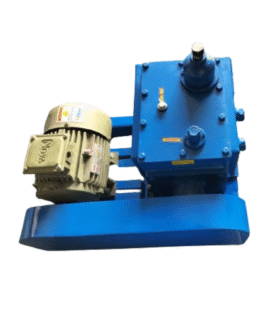

SINGLE STAGE

| Model No. | Max Vacuum | Approx Oil Filling Ltrs. | Free Air Displacement Lt./min, c.f.m, m3/hr | Drive Motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 I | 0.05 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 I | 0.05 mbar | 2 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.25 | ||

| JDO-150 I | 0.05 mbar | 3 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 0.50 | ||

| JDO-300 I | 0.05 mbar | 5 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.00 | ||

| JDO-500 I | 0.05 mbar | 9 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 1.50 | ||

| JDO-750 I | 0.05 mbar | 10 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 2.00 | ||

| JDO-1000 I | 0.05 mbar | 10 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 2.00 | ||

| JDO-1500 I | 0.05 mbar | 25 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 3.00 | ||

| JDO-2000 I | 0.05 mbar | 25 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 3.00 | ||

| JDO-3000 I | 0.05 mbar | 32 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 5.00 | ||

| JDO-5000 I | 0.05 mbar | 36 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 7.50 | ||

| JDO-7500 I | 0.05 mbar | 60 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 10.00 | ||

| JDO-10000 I | 0.05 mbar | 66 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 15.00 | ||

| JDO-15000 I | 0.05 mbar | 68 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 22.00 | ||

| JDO-20000 I | 0.05 mbar | 70 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 25.00 | ||

DOUBLE STAGE

| Model No. | max vacuum | approx oil filling ltrs. | free air displacement Lt./min, c.f.m, m3/hr | drive motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 II | 0.005 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 II | 0.005 mbar | 3 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.50 | ||

| JDO-150 II | 0.005 mbar | 4 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 1.00 | ||

| JDO-300 II | 0.005 mbar | 7 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.50 | ||

| JDO-500 II | 0.005 mbar | 12 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 2.00 | ||

| JDO-750 II | 0.005 mbar | 14 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 3.00 | ||

| JDO-1000 II | 0.005 mbar | 15 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 3.00 | ||

| JDO-1500 II | 0.005 mbar | 30 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 5.00 | ||

| JDO-2000 II | 0.005 mbar | 35 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 5.00 | ||

| JDO-3000 II | 0.005 mbar | 40 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 7.00 | ||

| JDO-5000 II | 0.005 mbar | 42 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 10.00 | ||

| JDO-7500 II | 0.005 mbar | 65 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 15.00 | ||

| JDO-10000 II | 0.005 mbar | 75 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 20.00 | ||

| JDO-15000 II | 0.005 mbar | 80 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 25.00 | ||

| JDO-20000 II | 0.005 mbar | 80 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 30.00 | ||

Field Application

- Laboratory Application of Chemical Plant.

- R&D Centre Vacuum Impregnation, Packing

- Vacuum Drying, Forming, Coating

- Lamp Industries, Leak Detection,

- Cryogenics, Distillation.Re-refining of oil

Capacity

- Max. Capacity: 50 LPM to 20,000 LPM (3.06 M3/hr.to 1204 M3/hr.)

- Max. Vacuum: Single Stage: 0.05 mm of Hg.

- Max. Vacuum: Two Stage: 0.005 mm of Hg.

- Recommend Motor: 0.25 HP to 25 HP, 1450 RPM Pump Speed: 500 RPM

Salient Features

- Robust Construction

- Compact, well-designed, and low-weight model

- Maximum Efficiency

- Trouble-free operation

- R&Easy and fast arrangement to change oil

- Thoroughly tested for seamless operation

- Easily handle dust-laden gases

- Built-in anti suck facility to prevent back of oil