ISO 9001 : 2015

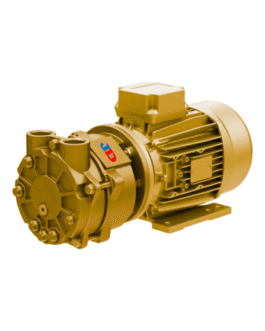

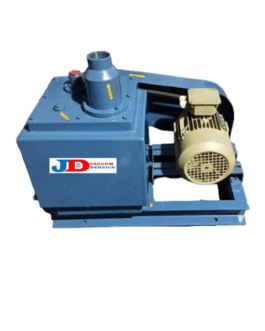

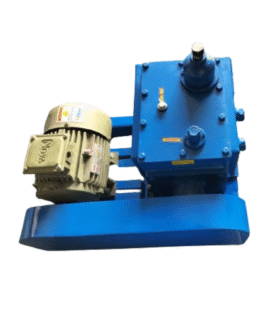

Vacuum Pump For Process Industries

Transform your production with the JD Vacuum Pump For Process Industries, designed to save energy while delivering exceptional results. Check it out!

- Type: WATER RING VACUUM PUMP

- Power: 3 to 90 hp

- Voltage: 220 - 440 V

- Max Flow Rate: 50 to 2025 M3/HR

- Motor Speed: 1440 RPM

- Vacuum: 710 MM/HG

- Usage/Application: Process Industries

- Country of Origin: Made in India

Description

Vacuum Pump For Process Industries

Introducing the JD Vacuum Pump, designed specifically for process industries, where efficiency meets reliability. Our vacuum pump offers a powerful solution for a variety of applications, ensuring a seamless experience in critical operations. With advanced technology and superior construction, it stands out as a trustworthy choice in the market.

Key Features and Benefits

The JD Vacuum Pump is engineered for high performance across various process industry segments. It boasts:

- Robust Design: Built to withstand demanding conditions while maintaining efficiency.

- Energy Efficient: Our vacuum pump minimizes energy usage without compromising performance, helping you save on operational costs.

- Versatile Applications: Suitable for diverse applications including food packaging, chemical processing, and more, making it a valuable asset in any production line.

With these features, our vacuum pump not only enhances operational efficiency but also contributes to sustainable practices within your facility.

Why Choose JD Vacuum Service?

At JD Vacuum Service, we prioritize our customers’ needs. Our vacuum pumps are backed by years of industry expertise and dedication to quality. Choosing us means you’re opting for:

- Expert Support: Our team of professionals is ready to assist you with setup, maintenance, and any inquiries to ensure maximum uptime.

- Reliable Supply Chain: Count on us for timely deliveries and consistent product availability to keep your processes uninterrupted.

- Customer Satisfaction: We are committed to delivering high-quality products and unmatched service to ensure your satisfaction.

Enhancing your production processes with our water ring vacuum pump will streamline operations and improve system reliability. Experience the ease and efficiency of our vacuum solutions tailor-made for process industries.

MOC of Pump

- Type: A (C.I. Construction)

- Type: C (All Internal Parts in SS 304 / SS 316)

- Type: SS (Complete SS 304 / SS 316)

Features

- Simple Construction

- High Capacity

- Trouble-Free Operation

- Low Maintenance

Applications

- Chemical Industries

- Pharmaceuticals

- Sterilizing

- Distillation, Evaporation & drying

- Filtration Processes

- Dehydrates

- Conveying Sucking

| Type JDWV | Speed rpm | suction capacity | Recommended motor hp | Water consumption ltr/min. |

|---|---|---|---|---|

| 1 | 2850 | 50 | 3 | 7 |

| 2 | 2850 | 80 | 5 | 10 |

| 3 | 2850 | 120 | 7.5 | 14 |

| 4 | 1440 | 160 | 7.5 | 15 |

| 5 | 1440 | 220 | 10 | 20 |

| 6 | 1440 | 330 | 15 | 30 |

| 7 | 1440 | 440 | 20 | 40 |

| 8 | 980 | 720 | 30 | 60 |

| 9 | 980 | 845 | 35 | 80 |

| 10 | 980 | 1080 | 40 | 100 |

| 11 | 725 | 1500 | 65 | 150 |

| 12 | 725 | 2025 | 90 | 200 |