ISO 9001 : 2015

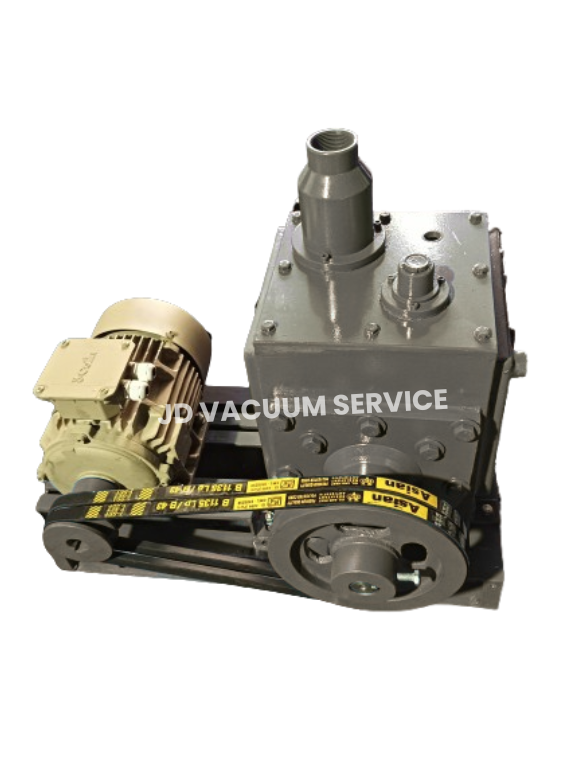

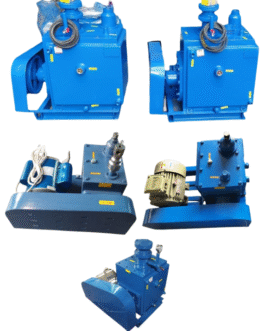

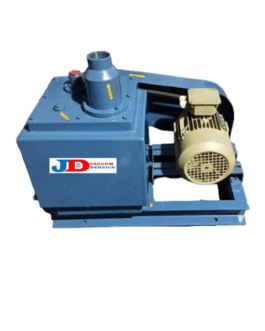

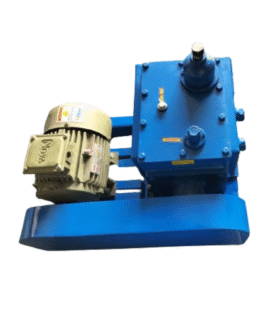

Vacuum Pump Oil Sealed

Discover the high performance Oil-Sealed Vacuum Pump from JD Vacuum Service. Built for durability, quiet operation, and powerful suction, it delivers exceptional vacuum stability for laboratory and industrial use. Enhance your workflow with a reliable, long life vacuum solution.

- Pump Type: Oil-Sealed Rotary Vane Vacuum Pump

- Ultimate Vacuum: Up to 0.005 mbar (varies by model)

- Motor Power: 0.25 HP to 5 HP (as required)

- Pumping Speed: 5 m³/hr to 300 m³/hr

- Cooling Method: Air-cooled / water cooling

- Oil Capacity: High-grade vacuum pump oil reservoir

- Noise Level: Low-noise operation between 50–70 dB

- Applications: Laboratory, industrial packaging, chemical processing, automation lines, vacuum filtration, and more

Description

Premium Oil-Sealed Vacuum Pump – Engineered for Reliability & Long-Life Performance

1. High-Efficiency Oil-Sealed Technology for Stable Vacuum Performance

Experience exceptional vacuum stability with the JD Vacuum Service Oil-Sealed Vacuum Pump, designed to deliver consistent suction, smoother operation, and superior sealing performance. Thanks to its advanced oil lubricated mechanism, the pump efficiently reduces friction and heat, ensuring seamless performance even during long production hours. Moreover, its robust construction enhances durability, making it ideal for laboratories, industrial processes, packaging, filtration, and R&D applications.

Additionally, the oil sealed design dramatically enhances vacuum depth, resulting in cleaner, faster, and more reliable evacuation cycles. Whether you need precision for sensitive equipment or powerful suction for demanding environments, this pump delivers unmatched performance.

2. Built for Industrial Demands – Strong, Quiet & Long-Lasting

Crafted with high grade materials, this vacuum pump ensures unparalleled longevity and minimal maintenance. Its heavy duty motor, combined with durable internal components, allows continuous operation without overheating. Furthermore, the pump is engineered to run quietly, reducing noise pollution in laboratories and production facilities.

The unit’s ergonomic design also simplifies serviceability. Because of its smart oil circulation system, the pump maintains optimal lubrication, preventing wear and extending service intervals. As a result, users enjoy a reliable machine with lower operating costs and longer service life.

3. Enhanced Features, Advanced Safety & Smooth Operation

This oil-sealed vacuum pump comes equipped with high-performance oil filters, precision-balanced rotors, and improved cooling features to guarantee safe and efficient operation. In addition, the pump ensures cleaner vacuum lines, thanks to effective oil mist reduction and contamination control.

Its safety-first engineering includes:

- Automatic oil return system

- Overload-protected motor

- High thermal endurance

- Secure, leak-proof design

Consequently, the pump supports critical processes with ease, ensuring your workflow remains uninterrupted and efficient every day.

SINGLE STAGE

| Model No. | Max Vacuum | Approx Oil Filling Ltrs. | Free Air Displacement Lt./min, c.f.m, m3/hr | Drive Motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 I | 0.05 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 I | 0.05 mbar | 2 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.25 | ||

| JDO-150 I | 0.05 mbar | 3 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 0.50 | ||

| JDO-300 I | 0.05 mbar | 5 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.00 | ||

| JDO-500 I | 0.05 mbar | 9 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 1.50 | ||

| JDO-750 I | 0.05 mbar | 10 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 2.00 | ||

| JDO-1000 I | 0.05 mbar | 10 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 2.00 | ||

| JDO-1500 I | 0.05 mbar | 25 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 3.00 | ||

| JDO-2000 I | 0.05 mbar | 25 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 3.00 | ||

| JDO-3000 I | 0.05 mbar | 32 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 5.00 | ||

| JDO-5000 I | 0.05 mbar | 36 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 7.50 | ||

| JDO-7500 I | 0.05 mbar | 60 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 10.00 | ||

| JDO-10000 I | 0.05 mbar | 66 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 15.00 | ||

| JDO-15000 I | 0.05 mbar | 68 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 22.00 | ||

| JDO-20000 I | 0.05 mbar | 70 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 25.00 | ||

DOUBLE STAGE

| Model No. | max vacuum | approx oil filling ltrs. | free air displacement Lt./min, c.f.m, m3/hr | drive motor | ||||

|---|---|---|---|---|---|---|---|---|

| JDO-50 II | 0.005 mbar | 2 | 50 LPM | 1.8 C.F.M. | 3 M3/HR | 0.25 | ||

| JDO-100 II | 0.005 mbar | 3 | 100 LPM | 3.5 C.F.M. | 6 M3/HR | 0.50 | ||

| JDO-150 II | 0.005 mbar | 4 | 150 LPM | 5.3 C.F.M. | 9 M3/HR | 1.00 | ||

| JDO-300 II | 0.005 mbar | 7 | 300 LPM | 10.6 C.F.M. | 18 M3/HR | 1.50 | ||

| JDO-500 II | 0.005 mbar | 12 | 500 LPM | 17.6 C.F.M. | 30 M3/HR | 2.00 | ||

| JDO-750 II | 0.005 mbar | 14 | 750 LPM | 26.5 C.F.M. | 45 M3/HR | 3.00 | ||

| JDO-1000 II | 0.005 mbar | 15 | 1000 LPM | 35.3 C.F.M. | 60 M3/HR | 3.00 | ||

| JDO-1500 II | 0.005 mbar | 30 | 1500 LPM | 53.0 C.F.M. | 90 M3/HR | 5.00 | ||

| JDO-2000 II | 0.005 mbar | 35 | 2000 LPM | 70.6 C.F.M. | 120 M3/HR | 5.00 | ||

| JDO-3000 II | 0.005 mbar | 40 | 3000 LPM | 106.0 C.F.M. | 180 M3/HR | 7.00 | ||

| JDO-5000 II | 0.005 mbar | 42 | 5000 LPM | 178.5 C.F.M. | 300 M3/HR | 10.00 | ||

| JDO-7500 II | 0.005 mbar | 65 | 7500 LPM | 265 C.F.M. | 450 M3/HR | 15.00 | ||

| JDO-10000 II | 0.005 mbar | 75 | 10000 LPM | 353 C.F.M. | 600 M3/HR | 20.00 | ||

| JDO-15000 II | 0.005 mbar | 80 | 15000 LPM | 530 C.F.M. | 900 M3/HR | 25.00 | ||

| JDO-20000 II | 0.005 mbar | 80 | 20000 LPM | 710 C.F.M. | 1200 M3/HR | 30.00 | ||

Field Application

- Laboratory Application of Chemical Plant.

- R&D Centre Vacuum Impregnation, Packing

- Vacuum Drying, Forming, Coating

- Lamp Industries, Leak Detection,

- Cryogenics, Distillation.Re-refining of oil

Capacity

- Max. Capacity: 50 LPM to 20,000 LPM (3.06 M3/hr.to 1204 M3/hr.)

- Max. Vacuum: Single Stage: 0.05 mm of Hg.

- Max. Vacuum: Two Stage: 0.005 mm of Hg.

- Recommend Motor: 0.25 HP to 25 HP, 1450 RPM Pump Speed: 500 RPM

Salient Features

- Robust Construction

- Compact, well-designed, and low-weight model

- Maximum Efficiency

- Trouble-free operation

- R&Easy and fast arrangement to change oil

- Thoroughly tested for seamless operation

- Easily handle dust-laden gases

- Built-in anti suck facility to prevent back of oil