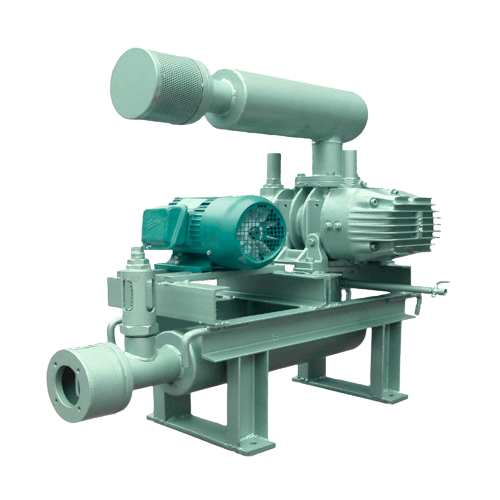

🌀 Introduction to Roots Blowers

Roots blowers (PD Blowers), also known as positive displacement rotary lobe blowers, are powerful machines designed to move air or gas in various industrial processes. Known for their durability and efficiency, they’ve become indispensable in applications ranging from pneumatic conveying to wastewater aeration.

They operate on a simple yet robust mechanism, delivering a constant volume of air at variable pressure. But despite their mechanical simplicity, there’s a lot to consider when selecting, operating, or maintaining a roots blower—especially when it comes to power consumption and performance.

Let’s dive into this power guide to uncover the 10 most critical things you need to know about roots blowers.

⚙️ How Roots Blowers Work

🔄 The Twin-Lobe Principle

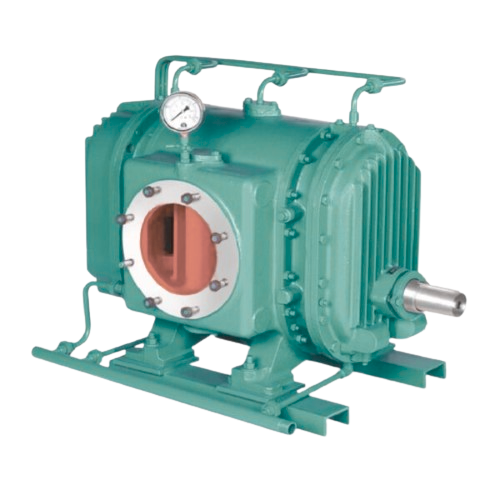

At the heart of every roots blower lies a pair of lobes rotating in opposite directions. These lobes trap air between themselves and the casing and push it toward the discharge port.

Unlike compressors that compress air within the chamber, roots blowers displace air without internal compression. This gives them their alternative name—positive displacement blowers.

🔬 Positive Displacement Explained

Positive displacement refers to a mechanism that traps a fixed volume of air and forces it through the system. This mechanism allows roots blowers to deliver a constant flow rate, regardless of pressure variations on the outlet side.

- Key characteristics of positive displacement in roots blowers:

- Constant volumetric flow

- Pressure depends on system resistance

- Smooth, pulsation-free airflow

🛠️ Types of Roots Blowers

⚙️ Single-Stage vs Multi-Stage

Single-stage roots blowers are most common in standard pressure applications. In contrast, multi-stage blowers offer higher pressure differentials by combining several stages in a series.

| Type | Applications | Pros | Cons |

|---|---|---|---|

| Single-Stage | General aeration, pneumatic transport | Cost-effective, simple | Limited pressure |

| Multi-Stage | High-pressure industrial tasks | Higher efficiency at pressure | More complex setup |

🛢️ Oil-Free vs Lubricated

- Oil-Free Blowers use pre-lubricated bearings and eliminate the risk of oil contamination.

- Lubricated Blowers require regular oil maintenance but often last longer under heavy use.

🧰 Applications of roots pump

🏭 Industrial Applications

- Roots blowers are workhorses in several industries:

- Chemical processing

- Cement manufacturing

- Textile drying

- Paper and pulp aeration

🚰 Wastewater Treatment Plants

In sewage treatment, roots blowers are used to aerate biological tanks, providing oxygen to bacteria that break down organic waste.

📦 Pneumatic Conveying Systems

Used for transporting powdered or granular materials:

- Flour

- Plastic pellets

- Cement

- Ash

⚡ Power Consumption of Roots Blowers

🔋 Key Factors Affecting Power Usage

The power consumption of roots blowers depends on:

- Pressure differential

- Airflow rate

- Blower efficiency

- Altitude and ambient temperature

A basic power formula:

Power (kW) = (Pressure × Flow Rate) / (Motor Efficiency × 102)

💡 Tips to Improve Energy Efficiency

- Use VFDs (Variable Frequency Drives)

- Install pressure relief valves

- Monitor system leaks

- Maintain optimal pressure levels

✅ Benefits of Using Roots Blowers

🔧 High Reliability and Low Maintenance

Roots blowers have very few moving parts. This minimizes downtime and makes them ideal for critical continuous operations.

🌬️ Consistent Airflow Delivery

Unlike centrifugal blowers, roots blowers aren’t affected much by pressure fluctuations. Their steady airflow makes them perfect for aeration and conveying.

🧱 Installation and Setup Guidelines

📍 Site Selection and Foundation

- Choose a dry, well-ventilated area

- Ensure a rigid concrete foundation

- Align blower and motor accurately to avoid vibration

🔌 Piping and Electrical Connections

- Use flexible connectors to reduce stress

- Ensure proper grounding of electrical units

- Avoid sharp bends in discharge piping

🧩 Common Problems and Troubleshooting

🔥 Overheating Issues

Possible causes:

- Blocked air filters

- High back pressure

- Insufficient lubrication

Solutions:

- Clean filters regularly

- Check system resistance

- Monitor oil levels

🔊 Unusual Noises or Vibrations

Can indicate:

- Worn bearings

- Misalignment

- Foreign particles in the blower

🧽 Maintenance Tips for Longer Life

🛢️ Regular Lubrication Checks

- Inspect oil levels weekly

- Replace oil every 2000 operating hours or as recommended

🧼 Filter and Seal Inspection

- Clean inlet filters every 100 hours

- Check seals for wear or cracks to avoid air leakage

🔄 Roots Blower vs Other Blower Types

⚙️ Roots vs Centrifugal

| Feature | Roots Blower | Centrifugal Blower |

|---|---|---|

| Airflow | Constant | Variable |

| Pressure | Low to Medium | High |

| Maintenance | Low | Medium |

🛠️ Roots vs Screw Blower

- Screw blowers are more efficient at high pressures.

- Roots blowers are more economical for basic operations.

🚀 Innovations and Future Trends

- Integration with IoT and remote monitoring

- Energy-efficient designs using composite materials

- Noise-reduction enhancements with advanced silencers

- Hybrid models that combine Roots and screw tech

❓ FAQs

roots pump

are used for aeration, conveying materials, vacuum applications, and industrial air supply.

Yes, especially when used with VFDs and in properly maintained systems.

Typically, synthetic gear oil like ISO VG 220 is used. Check the manufacturer’s recommendation.

Basic maintenance like oil checks and filter cleaning should be done weekly. Full servicing may be done every 6 months.

They are suitable for low to medium pressure. For high-pressure tasks, multi-stage or screw blowers are better suited.

They can be, but modern units with sound enclosures or silencers reduce noise considerably.

🏁 Conclusion

Roots blowers play a vital role across many industries due to their reliability, consistent performance, and cost-effectiveness. Understanding their power usage, maintenance needs, and application-specific benefits allows you to get the most out of your system while minimizing costs.

Whether you’re operating a wastewater plant or running pneumatic systems in manufacturing, investing in the right blower and using it efficiently can result in long-term operational success.

For more technical details and selection guides, visit trusted industry resources like JD VACUUM SERVICE selection guide.